Page 110 - Electrician - TT (Volume 1)

P. 110

ELECTRICIAN - CITS

System earthing

The earthing associated with current carrying conductor is normally essential to the security of the system is

known as system earthing. The system earthing is done at generating stations and substations.

Equipment earthing

Earthing of non-current carrying metal work and conductor which is essential for the safety of human life and

animals and the property is generally known as equipment earthing.

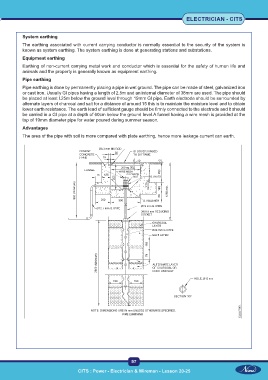

Pipe earthing

Pipe earthing is done by permanently placing a pipe in wet ground. The pipe can be made of steel, galvanized iron

or cast iron. Usually GI pipes having a length of 2.5m and an internal diameter of 38mm are used. The pipe should

be placed at least l.25m below the ground level through 19mm GI pipe. Earth electrode should be surrounded by

alternate layers of charcoal and salt for a distance of around 15 this is to maintain the moisture level and to obtain

lower earth resistance. The earth lead of sufficient gauge should be firmly connected to the electrode and it should

be carried in a GI pipe at a depth of 60cm below the ground level.A funnel having a wire mesh is provided at the

top of 19mm diameter pipe for water poured during summer season.

Advantages

The area of the pipe with soil is more compared with plate earthing, hence more leakage current can earth.

97

CITS : Power - Electrician & Wireman - Lesson 20-25 CITS : Power - Electrician & Wireman - Lesson 20-25