Page 119 - Electrician - TT (Volume 2)

P. 119

ELECTRICIAN - CITS

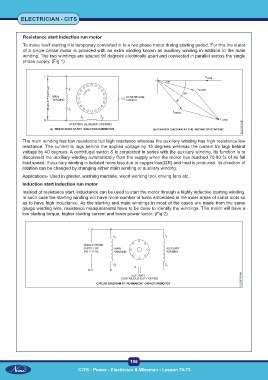

Resistance start induction run motor

To make itself starting it is temporary converted in to a two phase motor during starting period. For this the stator

of a single phase motor is provided with an extra winding known as auxiliary winding in addition to the main

winding. The two windings are spaced 90 degrees electrically apart and connected in parallel across the single

phase supply. (Fig 1)

The main winding has low resistance but high reactance whereas the auxiliary winding has high resistance low

reactance. The current Is lags behind the applied voltage by 15 degrees whereas the current Im lags behind

voltage by 40 degrees. A centrifugal switch S is connected in series with the auxiliary winding. Its function is to

disconnect the auxiliary winding automatically from the supply when the motor has reached 70-80 % of its full

load speed. If auxiliary winding is isolated more loss due to copper loss(I2R) and heat is produced. Its direction of

rotation can be changed by changing either main winding or auxiliary winding.

Applications- Used in grinder, washing machine, wood working tool, driving fans etc.

Induction start induction run motor

Instead of resistance start, inductance can be used to start the motor through a highly inductive starting winding.

In such case the starting winding will have more number of turns embedded in the inner areas of stator slots so

as to have high inductance. As the starting and main windings in most of the cases are made from the same

gauge winding wire, resistance measurements have to be done to identify the windings. This motor will have a

low starting torque, higher starting current and lower power factor. (Fig 2)

106

CITS : Power - Electrician & Wireman - Lesson 70-75