Page 326 - Electrician - TT (Volume 2)

P. 326

ELECTRICIAN - CITS

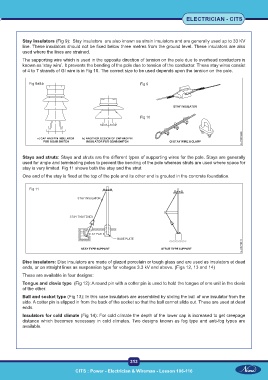

Stay insulators (Fig 9): Stay insulators are also known as strain insulators and are generally used up to 33 KV

line. These insulators should not be fixed below three metres from the ground level. These insulators are also

used where the lines are strained.

The supporting wire which is used in the opposite direction of tension on the pole due to overhead conductors is

known as ‘stay wire’. It prevents the bending of the pole due to tension of the conductor. These stay wires consist

of 4 to 7 strands of GI wire is in Fig 10. The correct size to be used depends upon the tension on the pole.

Fig 8a&b Fig 9

Fig 10

Stays and struts: Stays and struts are the different types of supporting wires for the pole. Stays are generally

used for angle and terminating poles to prevent the bending of the pole whereas struts are used where space for

stay is very limited. Fig 11 shows both the stay and the strut.

One end of the stay is fixed at the top of the pole and its other end is grouted in the concrete foundation.

Fig 11

Disc insulators: Disc insulators are made of glazed porcelain or tough glass and are used as insulators at dead

ends, or on straight lines as suspension type for voltages 3.3 kV and above. (Figs 12, 13 and 14)

These are available in four designs:

Tongue and clevis type (Fig 12): A round pin with a cotter pin is used to hold the tongue of one unit in the clevis

of the other.

Ball and socket type (Fig 13): In this case insulators are assembled by sliding the ball of one insulator from the

side. A cotter pin is slipped in from the back of the socket so that the ball cannot slide out. These are used at dead

ends.

Insulators for cold climate (Fig 14): For cold climate the depth of the lower cap is increased to get creepage

distance which becomes necessary in cold climates. Two designs known as fog type and anti-fog types are

available.

313

CITS : Power - Electrician & Wireman - Lesson 106-116 CITS : Power - Electrician & Wireman - Lesson 106-116