Page 242 - Electronic Mechanic - TP - Volume - 2

P. 242

ELECTRONICS MECHANIC - CITS

• Interpretation: A lit LED indicates that the corresponding input signal is active. If an input LED remains off

when it should be active, it could signify a wiring issue, sensor malfunction, or programming error.

• Representation: Multiple red LEDs labeled “I1”, “I2”, etc., corresponding to input channels.

• Significance: Shows the status of input signals received by the PLC.

• Interpretation: Lit when an input signal is active; off when the signal is inactive.

5 Output LEDs (Green)

• Indication: Similar to input LEDs, output LEDs indicate the status of output channels.

• Interpretation: A lit LED suggests that the associated output is energized. If an output LED remains off

when it should be active, it might indicate a fault in the control logic, output device, or wiring.

• Representation: Multiple red LEDs labeled “O1”, “O2”, etc., corresponding to output channels.

• Significance: Indicates whether the outputs are energized.

• Interpretation: Lit when the output is active; off when the output is inactive.

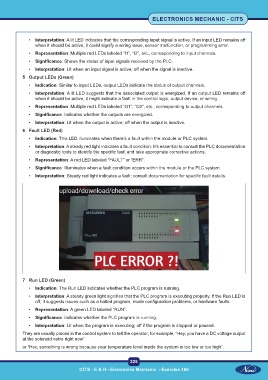

6 Fault LED (Red)

• Indication: This LED illuminates when there’s a fault within the module or PLC system.

• Interpretation: A steady red light indicates a fault condition. It’s essential to consult the PLC documentation

or diagnostic tools to identify the specific fault and take appropriate corrective actions.

• Representation: A red LED labeled “FAULT” or “ERR”.

• Significance: Illuminates when a fault condition occurs within the module or the PLC system.

• Interpretation: Steady red light indicates a fault; consult documentation for specific fault details.

7 Run LED (Green)

• Indication: The Run LED indicates whether the PLC program is running.

• Interpretation: A steady green light signifies that the PLC program is executing properly. If the Run LED is

off, it suggests issues such as a halted program, mode configuration problems, or hardware faults.

• Representation: A green LED labeled “RUN”.

• Significance: Indicates whether the PLC program is running.

• Interpretation: Lit when the program is executing; off if the program is stopped or paused.

They are usually placed in the control system to tell the operator, for example, “Hey, you have a DC voltage output

at the solenoid valve right now”

or “Hey, something is wrong because your temperature level inside the system is too low or too high”.

225

CITS : E & H - Electronics Mechanic - Exercise 180