Page 293 - Electronic Mechanic - TP - Volume - 2

P. 293

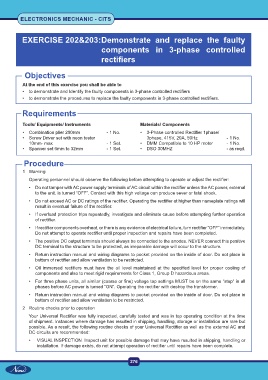

ELECTRONICS MECHANIC - CITS

EXERCISE 202&203: Demonstrate and replace the faulty

components in 3-phase controlled

rectifiers

Objectives

At the end of this exercise you shall be able to

• to demonstrate and Identify the faulty components in 3-phase controlled rectifiers

• to demonstrate the procedures to replace the faulty components in 3-phase controlled rectifiers.

Requirements

Tools/ Equipments/ Instruments Materials/ Components

• Combination plier 200mm - 1 No. • 3-Phase controlled Rectifier 1phase/

• Screw Driver set with neon tester 3phase, 415V, 20A, 50Hz - 1 No.

10mm- max - 1 Set. • DMM Compatible to 10 HP motor - 1 No.

• Spanner set 6mm to 32mm - 1 Set. • DSO 30MHZ - as reqd.

Procedure

1 Warning

Operating personnel should observe the following before attempting to operate or adjust the rectifier:

• Do not tamper with AC power supply terminals of AC circuit within the rectifier unless the AC power, external

to the unit, is turned “OFF”. Contact with this high voltage can produce sever or fatal shock.

• Do not exceed AC or DC ratings of the rectifier. Operating the rectifier at higher than nameplate ratings will

result in eventual failure of the rectifier.

• If overload protection trips repeatedly, investigate and eliminate cause before attempting further operation

of rectifier.

• If rectifier components overheat, or there is any evidence of electrical failure, turn rectifier “OFF” immediately.

Do not attempt to operate rectifier until proper inspection and repairs have been completed.

• The positive DC output terminals should always be connected to the anodes. NEVER connect this positive

DC terminal to the structure to be protected, as irreparable damage will occur to the structure.

• Return instruction manual and wiring diagrams to pocket provided on the inside of door. Do not place in

bottom of rectifier and allow ventilation to be restricted.

• Oil immersed rectifiers must have the oil level maintained at the specified level for proper cooling of

components and also to meet rigid requirements for Class 1, Group D hazardous areas.

• For three phase units, all similar (coarse or fine) voltage tap settings MUST be on the same “step” in all

phases before AC power is turned “ON”. Operating the rectifier with destroy the transformer.

• Return instruction manual and wiring diagrams to pocket provided on the inside of door. Do not place in

bottom of rectifier and allow ventilation to be restricted.

2 Routine checks prior to operation

Your Universal Rectifier was fully inspected, carefully tested and was in top operating condition at the time

of shipment. Instances where damage has resulted in shipping, handling, storage or installation are rare but

possible. As a result, the following routine checks of your Universal Rectifier as well as the external AC and

DC circuits are recommended:

• VISUAL INSPECTION. Inspect unit for possible damage that may have resulted in shipping, handling or

installation. If damage exists, do not attempt operation of rectifier until repairs have been complete.

276