Page 332 - Electronic Mechanic - TP - Volume - 2

P. 332

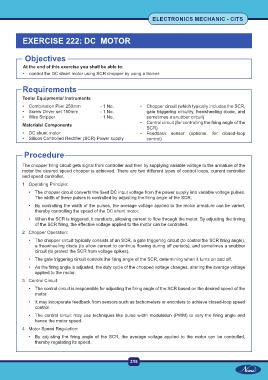

ELECTRONICS MECHANIC - CITS

EXERCISE 222: DC MOTOR

Objectives

At the end of this exercise you shall be able to:

• control the DC shunt motor using SCR chopper by using a trainer.

Requirements

Tools/ Equipments/ Instruments

• Combination Plier 250mm - 1 No. • Chopper circuit (which typically includes the SCR,

• Screw Driver set 150mm - 1 No. gate triggering circuitry, freewheeling diode, and

• Wire Stripper - 1 No. sometimes a snubber circuit)

• Control circuit (for controlling the firing angle of the

Materials/ Components

SCR)

• DC shunt motor • Feedback sensor (optional, for closed-loop

• Silicon Controlled Rectifier (SCR) Power supply control)

Procedure

The chopper firing circuit gets signal from controller and then by supplying variable voltage to the armature of the

motor the desired speed chopper is achieved. There are two different types of control loops, current controller

and speed controller.

1 Operating Principle:

• The chopper circuit converts the fixed DC input voltage from the power supply into variable voltage pulses.

The width of these pulses is controlled by adjusting the firing angle of the SCR.

• By controlling the width of the pulses, the average voltage applied to the motor armature can be varied,

thereby controlling the speed of the DC shunt motor.

• When the SCR is triggered, it conducts, allowing current to flow through the motor. By adjusting the timing

of the SCR firing, the effective voltage applied to the motor can be controlled.

2 Chopper Operation:

• The chopper circuit typically consists of an SCR, a gate triggering circuit (to control the SCR firing angle),

a freewheeling diode (to allow current to continue flowing during off periods), and sometimes a snubber

circuit (to protect the SCR from voltage spikes).

• The gate triggering circuit controls the firing angle of the SCR, determining when it turns on and off.

• As the firing angle is adjusted, the duty cycle of the chopped voltage changes, altering the average voltage

applied to the motor.

3 Control Circuit:

• The control circuit is responsible for adjusting the firing angle of the SCR based on the desired speed of the

motor.

• It may incorporate feedback from sensors such as tachometers or encoders to achieve closed-loop speed

control.

• The control circuit may use techniques like pulse width modulation (PWM) to vary the firing angle and

hence the motor speed.

4 Motor Speed Regulation:

• By adjusting the firing angle of the SCR, the average voltage applied to the motor can be controlled,

thereby regulating its speed.

315