Page 298 - CITS - Electronic Mechanic - TT - 2024

P. 298

ELECTRONICS MECHANIC - CITS

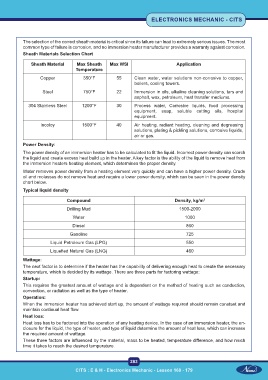

The selection of the correct sheath material is critical since its failure can lead to extremely serious issues. The most

common type of failure is corrosion, and no immersion heater manufacturer provides a warranty against corrosion.

Sheath Materials Selection Chart

Sheath Material Max Sheath Max WSI Application

Temperature

Copper 350°F 55 Clean water, water solutions non-corrosive to copper,

boilers, cooling towers.

Steel 750°F 22 Immersion in oils, alkaline cleaning solutions, tars and

asphalt, wax, petroleum, heat transfer mediums.

304 Stainless Steel 1200°F 30 Process water, Corrosive liquids, food processing

equipment, soap, soluble cutting oils, hospital

equipment.

Incoloy 1500°F 40 Air heating, radiant heating, cleaning and degreasing

solutions, plating & pickling solutions, corrosive liquids,

air or gas.

Power Density:

The power density of an immersion heater has to be calculated to fit the liquid. Incorrect power density can scorch

the liquid and create excess heat build up in the heater. A key factor is the ability of the liquid to remove heat from

the immersion heaters heating element, which determines the proper density.

Water removes power density from a heating element very quickly and can have a higher power density. Crude

oil and molasses do not remove heat and require a lower power density, which can be seen in the power density

chart below.

Typical liquid density

Compound Density, kg/m 3

Drilling Mud 1500-2000

Water 1000

Diesel 860

Gasoline 725

Liquid Petroleum Gas (LPG) 550

Liquefied Natural Gas (LNG) 460

Wattage:

The next factor is to determine if the heater has the capability of delivering enough heat to create the necessary

temperature, which is decided by its wattage. There are three parts for factoring wattage:

Startup:

This requires the greatest amount of wattage and is dependent on the method of heating such as conduction,

convection, or radiation as well as the type of heater.

Operation:

When the immersion heater has achieved start up, the amount of wattage required should remain constant and

maintain continual heat flow.

Heat loss:

Heat loss has to be factored into the operation of any heating device. In the case of an immersion heater, the en-

closure for the liquid, the type of heater, and type of liquid determine the amount of heat loss, which can increase

the required amount of wattage.

These three factors are influenced by the material, mass to be heated, temperature difference, and how much

time it takes to reach the desired temperature.

283

CITS : E & H - Electronics Mechanic - Lesson 160 - 179