Page 138 - CITS - Fitter Trade Pactical - Volume - 2

P. 138

FITTER - CITS

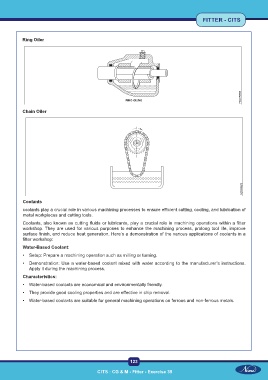

Ring Oiler

Chain Oiler

Coolants

coolants play a crucial role in various machining processes to ensure efficient cutting, cooling, and lubrication of

metal workpieces and cutting tools.

Coolants, also known as cutting fluids or lubricants, play a crucial role in machining operations within a fitter

workshop. They are used for various purposes to enhance the machining process, prolong tool life, improve

surface finish, and reduce heat generation. Here’s a demonstration of the various applications of coolants in a

fitter workshop:

Water-Based Coolant:

• Setup: Prepare a machining operation such as milling or turning.

• Demonstration: Use a water-based coolant mixed with water according to the manufacturer’s instructions.

Apply it during the machining process.

Characteristics:

• Water-based coolants are economical and environmentally friendly.

• They provide good cooling properties and are effective in chip removal.

• Water-based coolants are suitable for general machining operations on ferrous and non-ferrous metals.

123

CITS : CG & M - Fitter - Exercise 39 CITS : CG & M - Fitter - Exercise 39