Page 130 - CITS - Fitter - Trade Theory

P. 130

FITTER - CITS

- Carefully designed to prevent distortions during welding.

- Ensure proper component placement and stability to withstand welding stresses.

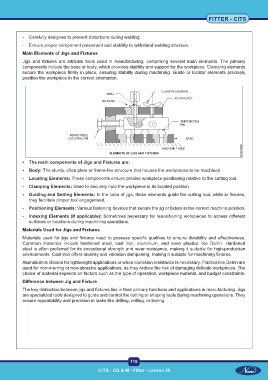

Main Elements of Jigs and Fixtures

Jigs and fixtures are intricate tools used in manufacturing, comprising several main elements. The primary

components include the base or body, which provides stability and support for the workpiece. Clamping elements

secure the workpiece firmly in place, ensuring stability during machining. Guide or locator elements precisely

position the workpiece in the correct orientation.

• The main components of Jigs and Fixtures are:

- Body: The sturdy, often plate or frame-like structure that houses the workpieces to be machined.

- Locating Elements: These components ensure precise workpiece positioning relative to the cutting tool.

- Clamping Elements: Used to securely hold the workpiece in its located position.

- Guiding and Setting Elements: In the case of jigs, these elements guide the cutting tool, while in fixtures,

they facilitate proper tool engagement.

- Positioning Elements: Various fastening devices that secure the jig or fixture in the correct machine position.

- Indexing Elements (if applicable): Sometimes necessary for repositioning workpieces to access different

surfaces or locations during machining operations.

Materials Used for Jigs and Fixtures

Materials used for jigs and fixtures need to possess specific qualities to ensure durability and effectiveness.

Common materials include hardened steel, cast iron, aluminium, and even plastics like Delrin. Hardened

steel is often preferred for its exceptional strength and wear resistance, making it suitable for high-production

environments. Cast iron offers stability and vibration dampening, making it suitable for machining fixtures.

Aluminium is chosen for lightweight applications or when corrosion resistance is necessary. Plastics like Delrin are

used for non-marring or non-abrasive applications, as they reduce the risk of damaging delicate workpieces. The

choice of material depends on factors such as the type of operation, workpiece material, and budget constraints.

Difference between Jig and Fixture

The key distinction between jigs and fixtures lies in their primary functions and applications in manufacturing. Jigs

are specialized tools designed to guide and control the cutting or shaping tools during machining operations. They

ensure repeatability and precision in tasks like drilling, milling, or boring.

115

CITS : CG & M - Fitter - Lesson 20 CITS : CG & M - Fitter - Lesson 20