Page 137 - CITS - Fitter - Trade Theory

P. 137

FITTER - CITS

6 Shut Height Adjustments: These mechanisms allow for the adjustment of the distance between the punch and

die, known as the shut height. Proper shut height adjustment is essential for achieving accurate and consistent

forming results.

7 Spring Mechanisms: In some press tools, especially those used for deep drawing or forming operations,

spring mechanisms may be incorporated to control the pressure applied during the operation and to facilitate

the ejection of the formed part from the die.

8 Wear Plates and Inserts: These components, often made of hardened steel or other wear-resistant materi-

als, are used to protect the press tool from wear and damage caused by repeated use and contact with the

workpiece.

9 Ejector System: In press tools used for high-volume production, an ejector system may be employed to

automatically remove the formed parts from the die after the operation is complete, increasing efficiency and

reducing cycle times.

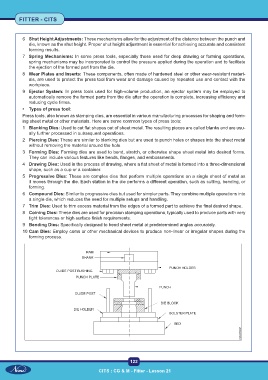

• Types of press tool:

Press tools, also known as stamping dies, are essential in various manufacturing processes for shaping and form-

ing sheet metal or other materials. Here are some common types of press tools:

1 Blanking Dies: Used to cut flat shapes out of sheet metal. The resulting pieces are called blanks and are usu-

ally further processed in subsequent operations.

2 Piercing Dies: These are similar to blanking dies but are used to punch holes or shapes into the sheet metal

without removing the material around the hole.

3 Forming Dies: Forming dies are used to bend, stretch, or otherwise shape sheet metal into desired forms.

They can include various features like bends, flanges, and embossments.

4 Drawing Dies: Used in the process of drawing, where a flat sheet of metal is formed into a three-dimensional

shape, such as a cup or a container.

5 Progressive Dies: These are complex dies that perform multiple operations on a single sheet of metal as

it moves through the die. Each station in the die performs a different operation, such as cutting, bending, or

forming.

6 Compound Dies: Similar to progressive dies but used for simpler parts. They combine multiple operations into

a single die, which reduces the need for multiple setups and handling.

7 Trim Dies: Used to trim excess material from the edges of a formed part to achieve the final desired shape.

8 Coining Dies: These dies are used for precision stamping operations, typically used to produce parts with very

tight tolerances or high surface finish requirements.

9 Bending Dies: Specifically designed to bend sheet metal at predetermined angles accurately.

10 Cam Dies: Employ cams or other mechanical devices to produce non-linear or irregular shapes during the

forming process.

122

CITS : CG & M - Fitter - Lesson 21