Page 26 - CITS - Fitter - Trade Theory

P. 26

FITTER - CITS

Mechanical fitter:Mechanical fitters are the most common type of fitters and are employed across a wide

range of industries, including petrochemicals, manufacturing, construction, automotive, and aerospace. They

are responsible for assembling and maintaining mechanical components such as equipment, engines, pumps,

conveyors, and other machinery. Mechanical fitters possess excellent technical skills and knowledge of various

tools and equipment.

Structural fitter: Structural fitters are involved in the fabrication and assembly of structural components used

in construction and manufacturing industries. They read blueprints, measure and cut materials, and weld or bolt

them together to construct frameworks, platforms, and supports.

Maintenance fitter: Maintenance fitters are responsible for the upkeep and repair of machinery and equipment.

They conduct regular inspections, troubleshoot issues, replace faulty parts, and perform preventative maintenance

tasks to ensure smooth operation.

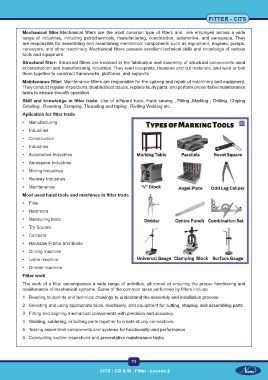

Skill and knowledge in fitter trade: Use of different tools, Hack sawing , Filling ,Marking , Drilling, Chiping

Grinding , Reaming ,Scraping, Threading and taping , Riviting Welding etc.

Aplication for fitter trade

• Manufacturing

• Industries

• Construction

• Industries

• Automotive Industries

• Aerospace Industries

• Mining Industries

• Railway Industries

• Maintenance

Most used hand tools and machines in fitter trade

• Files

• Hammers

• Measuring tools

• Try Square

• Callipers

• Hacksaw Frame and Blade

• Drilling machine

• Lathe machine

• Grinder machine

Fitter work

The work of a fitter encompasses a wide range of activities, all aimed at ensuring the proper functioning and

maintenance of mechanical systems. Some of the common tasks performed by fitters include

1 Reading blueprints and technical drawings to understand the assembly and installation process.

2 Selecting and using appropriate tools, machinery, and equipment for cutting, shaping, and assembling parts.

3 Fitting and aligning mechanical components with precision and accuracy.

4 Welding, soldering, or bolting parts together to create sturdy connections.

5 Testing assembled components and systems for functionality and performance.

6 Conducting routine inspections and preventative maintenance tasks.

11

CITS : CG & M - Fitter - Lesson 2