Page 104 - CTS - Mechanic Diesel - TP

P. 104

MECHANIC DIESEL - CITS

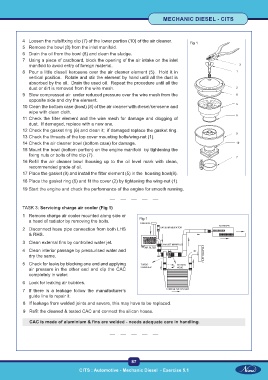

4 Loosen the nuts/fixing clip (7) of the lower portion (10) of the air cleaner. Fig 1

5 Remove the bowl (8) from the inlet manifold.

6 Drain the oil from the bowl (8) and clean the sludge.

7 Using a piece of cardboard, block the opening of the air intake on the inlet

manifold to avoid entry of foreign material.

8 Pour a little diesel/ kerosene over the air cleaner element (5). Hold it in

vertical position. Rotate and stir the element by hand until all the dust is

absorbed by the oil. Drain the used oil. Repeat the procedure until all the

dust or dirt is removed from the wire mesh.

9 Blow compressed air under reduced pressure over the wire mesh from the

opposite side and dry the element.

10 Clean the bottom case (bowl) (8) of the air cleaner with diesel/kerosene and

wipe with clean cloth.

11 Check the filter element and the wire mesh for damage and clogging of

dust. If damaged, replace with a new one.

12 Check the gasket ring (6) and clean it; if damaged replace the gasket ring.

13 Check the threads of the top cover mounting bolts/wing-nut (1).

14 Check the air cleaner bowl (bottom case) for damage.

15 Mount the bowl (bottom portion) on the engine manifold by tightening the

fixing nuts or bolts of the clip (7).

16 Refill the air cleaner bowl /housing up to the oil level mark with clean,

recommended grade of oil.

17 Place the gasket (9) and install the filter element (5) in the housing bowl(8).

18 Place the gasket ring (6) and fit the cover (2) by tightening the wing-nut (1).

19 Start the engine and check the performance of the engine for smooth running.

TASK 3: Servicing charge air cooler (Fig 1)

1 Remove charge air cooler mounted along side or

a head of radiator by removing the bolts. Fig 1

2 Disconnect hose pipe connection from both LHS

& RHS.

3 Clean external fins by controlled water jet.

4 Clean interior passage by pressurised water and

dry the same.

5 Check for leaks by blocking one end and applying

air pressure in the other end and dip the CAC

completely in water.

6 Look for leaking air bubbles.

7 If there is a leakage follow the manufacturer’s

guide line to repair it.

8 If leakage from welded joints and severe, this may have to be replaced.

9 Refit the cleaned & tested CAC and connect the silicon hoses.

CAC is made of aluminium & fins are welded - needs adequate care in handling.

87

CITS : Automotive - Mechanic Diesel - Exercise 5.1