Page 112 - CTS - Mechanic Diesel - TP

P. 112

MECHANIC DIESEL - CITS

5 Now the engine is ready for coupling with the FIP.

6 Prepare the F.I.P for coupling to the engine.

7 The pump plunger next to the drive end must be set to the commencement of delivery position for respective

direction of rotation.

8 Observe the timing marks on FI pump shaft and housing.

9 Rotate the pump camshaft and align the mark on the shaft taper with lines marked as R or L depending on the

rotation of the pump shaft.(Fig 3)

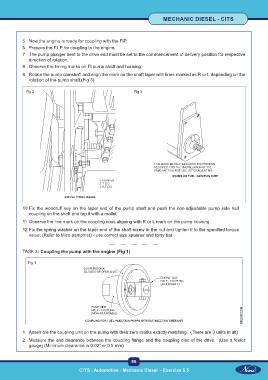

Fig 2 Fig 3

10 Fix the woodruff key on the taper end of the pump shaft and push the non-adjustable pump side half

coupling on the shaft and tap it with a mallet.

11 Observe the line mark on the coupling boss aligning with R or L mark on the pump housing.

12 Fix the spring washer on the taper end of the shaft-screw in the nut and tighten it to the specified torque

value. (Refer to Mico pamphlet) - use correct size spanner and tomy bar.

TASK 3: Coupling the pump with the engine (Fig 1)

Fig 1

1 Assemble the coupling unit on the pump with their zero marks exactly matching. (There are 3 units in all)

2 Measure the end clearance between the coupling flange and the coupling disc of the drive. (Use a feeler

gauge) (Minimum clearance is 0.02” or 0.5 mm)

95

CITS : Automotive - Mechanic Diesel - Exercise 5.5