Page 237 - CTS - Mechanic Diesel - TP

P. 237

MECHANIC DIESEL - CITS

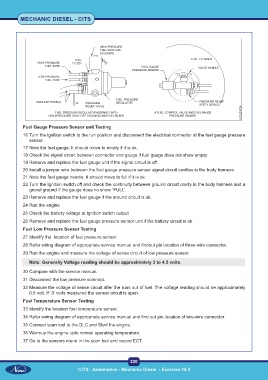

Fuel Gauge Pressure Sensor unit Testing

16 Turn the ignition switch to the run position and disconnect the electrical connector at the fuel gauge pressure

sensor.

17 Note the fuel gauge. It should move to empty if it is ok.

18 Check the signal circuit between connector and gauge if fuel gauge does not show empty.

19 Remove and replace the fuel gauge unit if the signal circuit is off.

20 Install a jumper wire between the fuel gauge pressure sensor signal circuit cavities in the body harness.

21 Note the fuel gauge needle. It should move to full if it is ok.

22 Turn the Ignition switch off and check the continuity between ground circuit cavity in the body harness and a

grovel ground if the gauge does no show `FULL’.

23 Remove and replace the fuel gauge if the around circuit is ok.

24 Run the engine

25 Check the battery voltage at Ignition switch output

26 Remove and replace the fuel gauge pressure sensor unit if the battery circuit is ok

Fuel Low Pressure Sensor Testing

27 Identify the location of fuel pressure sensor.

28 Refer wiring diagram of appropriate service manual and findout pin location of three wire connector.

29 Run the engine and measure the voltage of sense circuit of low pressure sensor.

Note: Generally Voltage reading should be approximately 3 to 4.5 volts.

30 Compare with the service manual.

31 Disconnect the low pressure solenoid.

32 Measure the voltage of sense circuit after the runs out of fuel. The voltage reading should be approximately

0.5 volt. If `0’ volts measured the sensor circuit is open.

Fuel Temperature Sensor Testing

33 Identify the location fuel temperature sensor.

34 Refer wiring diagram of appropriate service manual and find out pin location of two-wire connector.

35 Connect scan tool to the DLC and Start the engine.

36 Warmup the engine upto normal operating temperature.

37 Go to the sensors menu in the scan tool and record ECT.

220

CITS : Automotive - Mechanic Diesel - Exercise 14.3