Page 339 - CTS - Mechanic Diesel - TP

P. 339

MECHANIC DIESEL - CITS

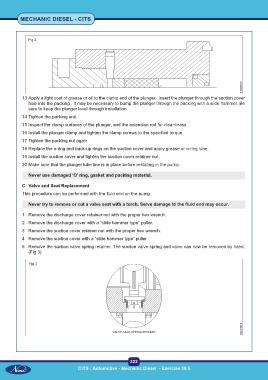

Fig 2

13 Apply a light coat of grease or oil to the clamp end of the plunger. Insert the plunger through the suction cover

hole into the packing . It may be necessary to bump the plunger through the packing with a slide hammer. Be

sure to keep the plunger level through installation

14 Tighten the packing unit.

15 Inspect the clamp surfaces of the plunger, and the extension rod for cleanliness

16 Install the plunger clamp and tighten the clamp screws to the specified torque

17 Tighten the packing nut again

18 Replace the o-ring and back-up rings on the suction cover and apply grease or o-ring lube.

19 Install the suction cover and tighten the suction cover retainer nut.

20 Make sure that the plunger lube line is in place before restating in the pump.

Never use damaged ‘O’ ring, gasket and packing material.

C Valve and Seat Replacement

This procedure can be performed with the fluid end on the pump.

Never try to remove or cut a valve seat with a torch. Serve damage to the fluid end may occur.

1 Remove the discharge cover retainer nut with the proper hex wrench.

2 Remove the discharge cover with a “slide hammer type” puller.

3 Remove the suction cover retainer nut with the proper hex wrench.

4 Remove the suction cover with a “slide hammer type” puller

5 Remove the suction valve spring retainer. The suction valve spring and valve can now be removed by hand.

(Fig 3)

Fig 3

322

CITS : Automotive - Mechanic Diesel - Exercise 18.5