Page 84 - CTS - Mechanic Diesel - TP

P. 84

MECHANIC DIESEL - CITS

EXERCISE 3.3: Overhauling the turbo charger

Objectives

At the end of this exercise you shall be able to

• remove turbo charger from vehicle

• dismantle turbo charger

• clean, replace or repair defective parts

• assemble and check turbo charger

• refit turbo charger on vehicle and start the engine.

Requirements

Tools/Instruments Materials/Components

• Trainee’s tool kit - 1 No • Kerosene - as reqd.

• Circlip plier - 1 No • Cotton cloth - as reqd.

• Box spanner - 1 set • Anti corrosive solution - as reqd.

• Dial gauge - 1 No • Cleaning brush - 1 No.

• Torque wrench - 1 No • Turbo charger accessories - as reqd.

• Plastic mallet - 1 No

Equipments/Machines

• Work bench - 1 No.

• Turbo charger - 1 No.

Procedure

Removal

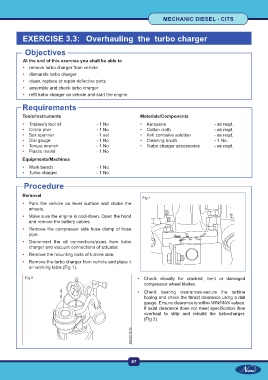

Fig 1

• Park the vehicle on level surface and choke the

wheels.

• Make sure the engine is cool-down. Open the hood

and remove the battery cables.

• Remove the compressor side hose clamp of hose

pipe.

• Disconnect the oil connections/pipes from turbo

charger and vacuum connections of actuator.

• Remove the mounting bolts of turbine side.

• Remove the turbo charger from vehicle and place it

on working table (Fig 1).

Fig 2 • Check visually for cracked, bent or damaged

compressor wheel blades.

• Check bearing clearances-secure the turbine

hosing and check the thrust clearance using a dial

gauge. Ensure clearance is within MIN/MAX values.

If axial clearance does not meet specification than

overhaul to strip and rebuild the turbocharger.

(Fig 2)

67