Page 132 - Mechanic Diesel - TT

P. 132

MECHANIC DIESEL - CITS

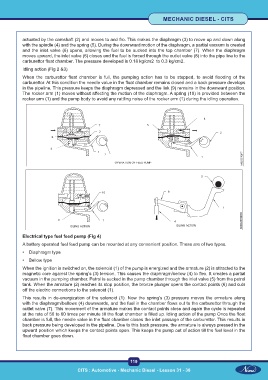

actuated by the camshaft (2) and moves to and fro. This makes the diaphragm (3) to move up and down along

with the spindle (4) and the spring (5). During the downward motion of the diaphragm, a partial vacuum is created

and the inlet valve (6) opens, allowing the fuel to be sucked into the top chamber (7). When the diaphragm

moves upward, the inlet valve (6) closes and the fuel is forced through the outlet valve (8) into the pipe line to the

carburettor float chamber. The pressure developed is 0.18 kg/cm2 to 0.3 kg/cm2.

Idling action (Fig 2 &3)

When the carburettor float chamber is full, the pumping action has to be stopped, to avoid flooding of the

carburettor. At this condition the needle value in the float chamber remains closed and a back pressure develops

in the pipeline. This pressure keeps the diaphragm depressed and the link (9) remains in the downward position.

The rocker arm (1) moves without affecting the motion of the diaphragm. A spring (10) is provided between the

rocker arm (1) and the pump body to avoid any rattling noise of the rocker arm (1) during the idling operation.

Electrical type fuel feed pump (Fig 4)

A battery operated fuel feed pump can be mounted at any convenient position. These are of two types.

• Diaphragm type

• Bellow type

When the ignition is switched on, the solenoid (1) of the pump is energized and the armature (2) is attracted to the

magnetic core against the spring’s (3) tension. This causes the diaphragm/bellow (4) to flex. It creates a partial

vacuum in the pumping chamber. Petrol is sucked in the pump chamber through the inlet valve (5) from the petrol

tank. When the armature (2) reaches its stop position, the bronze plunger opens the contact points (6) and cuts

off the electric connections to the solenoid (1).

This results in de-energization of the solenoid (1). Now the spring’s (3) pressure moves the armature along

with the diaphragm/bellows (4) downwards, and the fuel in the chamber flows out to the carburettor through the

outlet valve (7). This movement of the armature makes the contact points close and again the cycle is repeated

at the rate of 50 to 60 times per minute till the float chamber is filled up. Idling action of the pump Once the float

chamber is full, the needle valve in the float chamber closes the inlet passage of the carburettor. This results in

back pressure being developed in the pipeline. Due to this back pressure, the armature is always pressed in the

upward position which keeps the contact points open. This keeps the pump out of action till the fuel level in the

float chamber goes down.

119

CITS : Automotive - Mechanic Diesel - Lesson 31 - 38 CITS : Automotive - Mechanic Diesel - Lesson 31 - 38