Page 167 - Mechanic Diesel - TT

P. 167

MECHANIC DIESEL - CITS

Oil pump is most important part of oil lubrication system because of it is main unit to which pressure create on

oil. It is drive by a timing gears. It is construction is simple, inside of these pump only two gears rotate inside. The

housing of a unit called drive gear which drive the cam shaft and another one is driven gear as shown in given

diagram.

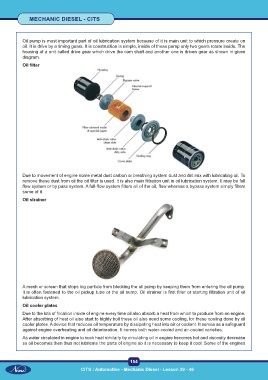

Oil filter

Due to movement of engine some metal dust carbon or breathing system dust and dirt mix with lubricating oil. To

remove these dust from oil the oil filter is used. It is also main filtration unit in oil lubrication system. It may be full

flow system or by pass system. A full-flow system filters all of the oil, flow whereas a bypass system simply filters

some of it.

Oil strainer

A mesh or screen that stops big particle from blocking the oil pump by keeping them from entering the oil pump.

It is often fastened to the oil pickup tube or the oil sump. Oil strainer is first filter or starting filtration unit of oil

lubrication system.

Oil cooler plates

Due to the lots of frication inside of engine every time oil also absorb a heat from which to produce from an engine.

After absorbing of heat oil also start to highly boil these oil also need some cooling, for these cooling done by oil

cooler plates. A device that reduces oil temperature by dissipating heat into air or coolant. It serves as a safeguard

against engine overheating and oil deterioration. It comes both water-cooled and air-cooled varieties.

As water circulated in engine to suck heat similarly by circulating oil in engine becomes hot and viscosity decrease

so oil becomes then thus not lubricate the parts of engine so it is necessary to keep it cool. Some of the engines

154

CITS : Automotive - Mechanic Diesel - Lesson 39 - 46