Page 13 - CITS - Welder - Trade Theory

P. 13

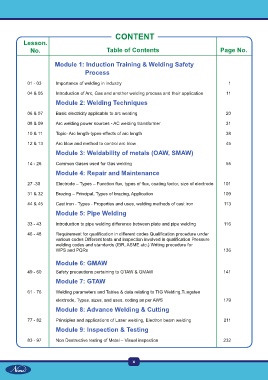

CONTENT

Lesson.

No. Table of Contents Page No.

Module 1: Induction Training & Welding Safety

Process

01 - 03 Importance of welding in industry 1

04 & 05 Introduction of Arc, Gas and another welding process and their application 11

Module 2: Welding Techniques

06 & 07 Basic electricity applicable to arc welding 20

08 & 09 Arc welding power sources - AC welding transformer 31

10 & 11 Topic- Arc length-types-effects of arc length 38

12 & 13 Arc blow and method to control arc blow 45

Module 3: Weldability of metals (OAW, SMAW)

14 - 26 Common Gases used for Gas welding 55

Module 4: Repair and Maintenance

27 -30 Electrode – Types – Function flux, types of flux, coating factor, size of electrode 101

31 & 32 Brazing – Principal, Types of brazing, Application 109

44 & 45 Cast iron - Types - Properties and uses, welding methods of cast iron 113

Module 5: Pipe Welding

33 - 43 Introduction to pipe welding difference between plate and pipe welding 116

46 - 48 Requirement for qualification in different codes Qualification procedure under

various codes Different tests and inspection involved in qualification Pressure

welding codes and standards (IBR, ASME etc.) Writing procedure for

WPS and PQRs 136

Module 6: GMAW

49 - 60 Safety precautions pertaining to GTAW & GMAW 141

Module 7: GTAW

61 - 76 Welding parameters and Tables & data relating to TIG Welding.Tungsten

electrode, Types, sizes, and uses. coding as per AWS 179

Module 8: Advance Welding & Cutting

77 - 82 Principles and applications of Laser welding, Electron beam welding 211

Module 9: Inspection & Testing

83 - 97 Non Destructive testing of Metal – Visual inspection 232

x