Page 143 - CITS - Welder - Trade Theory

P. 143

WELDER - CITS

In the case of joints which are not free to expand i.e., restrained joints and in joints in which there is a stress

already present before welding, the residual stresses will be more after cooling of the joint. If these residual

stresses are not removed after welding, then the joint will fail or distort when they are put into use or the joint is

machined or the joint is subjected to dynamic loading.

To avoid the above problems a welded job is usually either normalised or annealed or stress-relieve

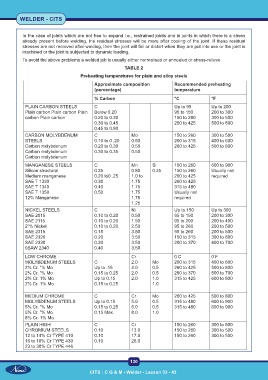

TABLE 2

Preheating temperatures for plain and alloy steels

Approximate composition Recommended preheating

(percentage) temperature

% Carbon °C °F

PLAIN CARBON STEELS C Up to 95 Up to 200

Plain carbon Plain carbon Plain Below 0.20 95 to 150 200 to 300

carbon Plain carbon 0.20 to 0.30 150 to 280 300 to 500

0.30 to 0.45 260 to 425 500 to 800

0.45 to 0.80

CARBON MOLYBDENUM C Mo 150 to 260 300 to 500

STEELS 0.10 to 0 .20 0.50 200 to 315 400 to 600

Carbon molybdenum 0.20 to 0.30 0.50 260 to 425 500 to 800

Carbon molybdenum 0.30 to 0.35 0.50

Carbon molybdenum

MANGANESE STEELS C Mn Si 150 to 260 600 to 900

Silicon structural 0.35 0.80 0.25 150 to 260 Usually not

Medium manganese 0.20 to0 .25 1.0 to 200 to 425 required

SAE T 1330 0.30 1.75 260 to 425

SAE T 1340 0.40 1.75 315 to 480

SAE T 1350 0.50 1.75 Usually not

12% Manganese 1.75 required

1.25

NICKEL STEELS C Ni Up to 150 Up to 300

SAE 2015 0.10 to 0.20 0.50 95 to 150 200 to 300

SAE 2115 0.10 to 0.20 1.50 95 to 200 200 to 400

2”% Nickel 0.10 to 0.20 2.50 95 to 260 200 to 500

SAE 2315 0.15 3.50 95 to 260 200 to 500

SAE 2320 0.20 3.50 150 to 315 300 to 600

SAE 2330 0.30 3.50 200 to 370 400 to 700

0SAW 2340 0.40 3.50

LOW CHROME Cr 0 C 0 F

MOLYBDENUM STEELS C 2.0 Mo 200 to 315 400 to 600

2% Cr. ”% Mo Up to .15 2.0 0.5 260 to 425 500 to 800

2% Cr. ”% Mo 0.15 to 0.25 2.0 0.5 260 to 370 500 to 700

2% Cr. 1% Mo Up to 0.15 2.0 1.0 315 to 425 600 to 800

2% Cr. 1% Mo 0.15 to 0.25 1.0

MEDIUM CHROME C Cr Mo 260 to 425 500 to 800

MOLYBDENUM STEELS Up to 0.15 5.0 0.5 315 to 480 600 to 900

5% Cr. ”% Mo 0.15 to 0.25 5.0 0.5 315 to 480 600 to 900

5% Cr. ”% Mo 0.15 Max. 8.0 1.0

8% Cr. 1% Mo

PLAIN HIGH C Cr 150 to 260 300 to 500

CHROMIUM STEELS 0.10 13.0 150 to 260 300 to 500

12 to 14% Cr TYPE 410 0.10 17.0 150 to 260 300 to 500

16 to 18% Cr TYPE 430 0.10 26.0

23 to 30% Cr TYPE 446

130

CITS : C G & M - Welder - Lesson 33 - 43 CITS : C G & M - Welder - Lesson 33 - 43