Page 268 - CITS - Welder - Trade Theory

P. 268

WELDER - CITS

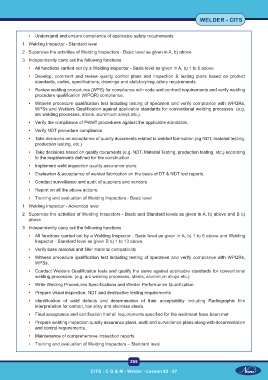

• Understand and ensure compliance of applicable safety requirements

1 Welding Inspector - Standard level

2 Supervise the activities of Welding Inspectors - Basic level as given in A, b) above

3 Independently carry out the following functions

• All functions carried out by a Welding Inspector - Basic level as given in A, b) 1 to 6 above

• Develop, comment and review quality control plans and inspection & testing plans based on product

standards, codes, specifications, drawings and statutory/regulatory requirements.

• Review welding procedures (WPS) for compliance with code and contract requirements and verify welding

procedure qualification (WPQR) compliance.

• Witness procedure qualification test including testing of specimen and verify compliance with WPQRs,

WPSs and Welders Qualification against applicable standards for conventional welding processes. (e.g.

arc welding processes, steels, aluminium alloys etc.)

• Verify the compliance of PWHT procedures against the applicable standards.

• Verify NDT procedure compliance

• Take decisions on acceptance of quality documents related to welded fabrication (eg NDT, material testing,

production testing, etc.)

• Take decisions based on quality documents (e.g. NDT, Material Testing, production testing, etc.) according

to the requirements defined for the construction

• Implement weld inspection quality assurance plans

• Evaluation & acceptance of welded fabrication on the basis of DT & NDT test reports.

• Conduct surveillance and audit of suppliers and vendors

• Report on all the above actions.

• Training and evaluation of Welding Inspectors - Basic level

1 Welding Inspector - Advanced level

2 Supervise the activities of Welding Inspectors - Basic and Standard levels as given in A, b) above and B b)

above

3 Independently carry out the following functions

• All functions carried out by a Welding Inspector - Basic level as given in A, b) 1 to 6 above and Welding

Inspector - Standard level as given B b) 1 to 13 above

• Verify base material and filler material compatibility

• Witness procedure qualification test including testing of specimen and verify compliance with WPQRs,

WPSs.

• Conduct Welders Qualification tests and qualify the same against applicable standards for conventional

welding processes. (e.g. arc welding processes, steels, aluminium alloys etc.)

• Write Welding Procedures Specifications and Welder Performance Qualification

• Prepare visual inspection, NDT and destructive testing requirements

• Identification of weld defects and determination of their acceptability including Radiographic film

interpretation for carbon, low alloy and stainless steels.

• Final acceptance and certification that all requirements specified for the weldment have been met

• Prepare welding inspection quality assurance plans, audit and surveillance plans along with documentation

and control requirements.

• Maintenance of comprehensive inspection reports

• Training and evaluation of Welding Inspectors – Standard level

255

CITS : C G & M - Welder - Lesson 83 - 97