Page 30 - CITS - Welder - Trade Theory

P. 30

WELDER - CITS

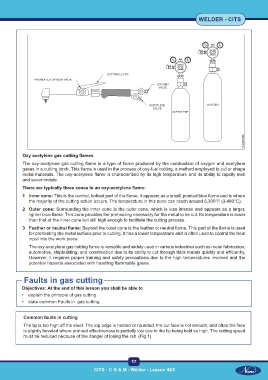

Oxy acetylene gas cutting flames

The oxy-acetylene gas cutting flame is a type of flame produced by the combustion of oxygen and acetylene

gases in a cutting torch. This flame is used in the process of oxy-fuel cutting, a method employed to cut or shape

metal materials. The oxy-acetylene flame is characterized by its high temperature and its ability to rapidly melt

and sever metals.

There are typically three zones in an oxy-acetylene flame:

1 Inner cone: This is the central, hottest part of the flame. It appears as a small, pointed blue flame and is where

the majority of the cutting action occurs. The temperature in this zone can reach around 6,300°F (3,480°C).

2 Outer cone: Surrounding the inner cone is the outer cone, which is less intense and appears as a larger,

lighter blue flame. This zone provides the preheating necessary for the metal to be cut. Its temperature is lower

than that of the inner cone but still high enough to facilitate the cutting process.

3 Feather or neutral flame: Beyond the outer cone is the feather or neutral flame. This part of the flame is used

for preheating the metal surface prior to cutting. It has a lower temperature and is often used to control the heat

input into the work piece.

The oxy-acetylene gas cutting flame is versatile and widely used in various industries such as metal fabrication,

automotive, shipbuilding, and construction due to its ability to cut through thick metals quickly and efficiently.

However, it requires proper training and safety precautions due to the high temperatures involved and the

potential hazards associated with handling flammable gases.

Faults in gas cutting

Objectives: At the end of this lesson you shall be able to

• explain the principle of gas cutting

• state common Faults in gas cutting.

Common faults in cutting

The tip is too high off the steel. The top edge is heated or rounded, the cut face is not smooth, and often the face

is slightly beveled where preheat effectiveness is partially lost due to the tip being held so high. The cutting speed

must be reduced because of the danger of losing the cut. (Fig 1)

17

CITS : C G & M - Welder - Lesson 4&5 CITS : C G & M - Welder - Lesson 4&5