Page 90 - CITS - ED - ELECTRICAL

P. 90

ENGINEERING DRAWING - CITS

Special Nuts

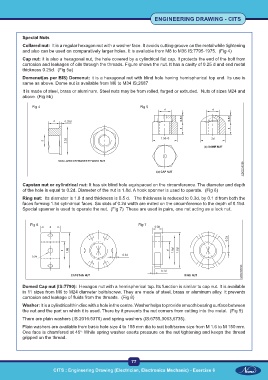

Collared nut: It is a regular hexagon nut with a washer face. It avoids cutting groove on the metal while tightening

and also can be used on comparatively larger holes. It is available from M8 to M36 IS:7795-1975. (Fig 4)

Cap nut: it is also a hexagonal nut, the hole covered by a cylindrical flat cap. It protects the end of the bolt from

corrosion and leakages of oils through the threads. Figure shows the nut. It has a cavity of 0.25 d and end metal

thickness 0.25d. (Fig 5a)

Domenut(as per BIS) Domenut: it is a hexagonal nut with blind hole having hemispherical top end. Its use is

same as above. Dome nut is available from M6 to M34 IS;2687

It is made of steel, brass or aluminum. Steel nuts may be from rolled, forged or extruded. Nuts of sizes M24 and

above. (Fig 5b)

Fig 4 Fig 5

Capstan nut or cylindrical nut: It has six blind hole equispaced on the circumference. The diameter and depth

of the hole is equal to 0.2d. Diameter of the nut is 1.8d. A hook spanner is used to operate. (Fig 6)

Ring nut: Its diameter is 1.8 d and thickness is 0.5 d. The thickness is reduced to 0.3d, by 0.1 d from both the

faces forming 1.5d cylindrical faces. Six slots of 0.2d width are milled on the circumference to the depth of 0.15d.

Special spanner is used to operate the nut. (Fig 7) These are used in pairs, one nut acting as a lock nut.

Fig 6 Fig 7

Domed Cap nut (IS:7790): Hexagon nut with a hemispherical top. Its function is similar to cap nut. It is available

in 11 sizes from M6 to M24 diameter bolts/screw. They are made of steel, brass or aluminum alloy. It prevents

corrosion and leakage of fluids from the threads. (Fig 8)

Washer: It is a cylindrical thin disc with a hole in the centre. Washer helps to provide smooth bearing surface between

the nut and the part on which it is used. There by it prevents the nut corners from cutting into the metal. (Fig 9)

There are plain washers (IS:2016:5370) and spring washers (IS:6755,3063,6735).

Plain washers are available from basic hole size 4 to 155 mm dia to suit bolt/screw size from M 1.6 to M 150 mm.

One face is chamfered at 45 While spring washer exerts pressure on the nut tightening and keeps the thread

o.

gripped on the thread.

77

CITS : Engineering Drawing (Electrician, Electronics Mechanic) - Exercise 6