Page 124 - CITS - Electrician - Trade Practical

P. 124

ELECTRICIAN - CITS

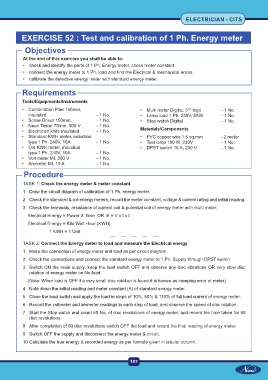

EXERCISE 52 : Test and calibration of 1 Ph. Energy meter

Objectives

At the end of this exercise you shall be able to:

• check and identify the parts of 1 Ph. Energy meter, check meter constant

• connect the energy meter to 1 Ph. load and find the Electrical & mechanical errors

• calibrate the defective energy meter with standard energy meter.

Requirements

Tools/Equipments/Instruments

• Combination Plier 165mm, • Multi meter Digital, 3 digit - 1 No.

1/2

insulated - 1 No. • Lamp load 1 Ph. 230V, 5KW - 1 No.

• Screw Driver 150mm, - 1 No. • Stop watch Digital - 1 No.

• Neon Tester 75mm, 500 V - 1 No.

• Electrician knife insulated - 1 No. Materials/Components

• Standard KWH meter, induction • PVC copper wire 1.5 sq.mm - 2 meter

type 1 Ph. 240V, 10A - 1 No. • Test lamp 100 W, 230V - 1 No.

• Old KWH meter, induction • DPST switch 16 A, 230 V - 1 No.

type 1 Ph. 240V, 10A - 1 No.

• Volt meter MI, 300 V - 1 No.

• Ammeter MI, 10 A - 1 No.

Procedure

TASK 1: Check the energy meter & meter constant

1 Draw the circuit diagram of calibration of 1 Ph. energy meter.

2 Check the standard & old energy meters, record the meter constant, voltage & current rating and initial reading.

3 Check the terminals, resistance of current coil & potential coil of energy meter with multi meter.

Electrical Energy = Power X Time OR E = V x I x t

Electrical Energy = Kilo Watt Hour (KWH)

1 KWH = 1 Unit

TASK 2: Connect the Energy meter to load and measure the Electrical energy

1 Make the connection of energy meter and load as per circuit diagram.

2 Check the connections and connect the standard energy meter to 1 Ph. Supply through DPST switch.

3 Switch ON the main supply, keep the load switch OFF and observe any disc vibrations OR very slow disc

rotation of energy meter on No-load.

(Note: When load is OFF if a very small disc rotation is found it is known as creeping error of meter)

4 Note down the initial reading and meter constant (K) of standard energy meter.

5 Close the load switch and apply the load in steps of 10%, 50% & 110% of full load current of energy meter.

6 Record the voltmeter and ammeter readings in each step of load, and observe the speed of disc rotation.

7 Start the Stop watch and count 50 No. of disc revolutions of energy meter, and record the time taken for 50

disc revolutions.

8 After completion of 50 disc revolutions switch OFF the load and record the final reading of energy meter.

9 Switch OFF the supply and disconnect the energy meter & circuit.

10 Calculate the true energy & recorded energy as per formula given in tabular column.

107

CITS : Power - Electrician & Wireman - Exercise 51