Page 245 - CITS - Electrician - Trade Practical

P. 245

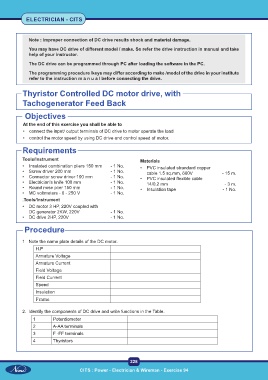

ELECTRICIAN - CITS

Note : Improper connection of DC drive results shock and material damage.

You may have DC drive of different model / make. So refer the drive instruction in manual and take

help of your instructor.

The DC drive can be programmed through PC after loading the software in the PC.

The programming procedure /keys may differ according to make /model of the drive in your institute

refer to the instruction m a n u a l before connecting the drive.

Thyristor Controlled DC motor drive, with

Tachogenerator Feed Back

Objectives

At the end of this exercise you shall be able to

• connect the input/ output terminals of DC drive to motor operate the load

• control the motor speed by using DC drive and control speed of motor.

Requirements

Tools/Instrument Materials

• Insulated combination pliers 150 mm - 1 No. • PVC insulated strandard copper

• Screw driver 200 mm - 1 No. cable 1.5 sq.mm, 660V - 15 m.

• Connector screw driver 100 mm - 1 No. • PVC insulated flexible cable

• Electrician’s knife 100 mm - 1 No. 14/0.2 mm - 3 m.

• Round nose plier 150 mm - 1 No. • Insulation tape - 1 No.

• MC voltmeters - 0 - 250 V - 1 No.

.Tools/Instrument

• DC motor 3 HP, 220V coupled with

DC generator 2KW, 220V - 1 No.

• DC drive 2HP, 220V - 1 No.

Procedure

1 Note the name plate details of the DC motor.

H.P

Armature Voltage

Armature Current

Field Voltage

Field Current

Speed

Insulation

Frame

2. Identify the components of DC drive and write functions in the Table.

1 Potentiometer

2 A-AA terminals

3 F -FF terminals

4 Thyristors

228

CITS : Power - Electrician & Wireman - Exercise 94