Page 36 - CITS - Electrician - Trade Practical

P. 36

v

ELECTRICIAN - CITS

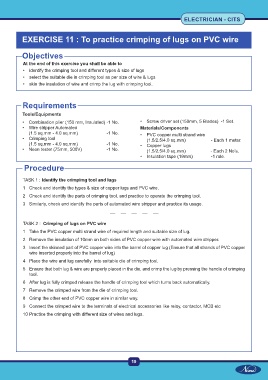

EXERCISE 11 : To practice crimping of lugs on PVC wire

Objectives

At the end of this exercise you shall be able to

• identify the crimping tool and different types & size of lugs

• select the suitable die in crimping tool as per size of wire & lugs

• skin the insulation of wire and crimp the lug with crimping tool.

Requirements

Tools/Equipments

• Combination plier (150 mm, Insulated) -1 No. • Screw driver set (150mm, 5 Blades) -1 Set.

• Wire stripper Automated Materials/Components

(1.5 sq.mm - 4.0 sq.mm) -1 No. • PVC copper multi strand wire

• Crimping tool (1.5/2.5/4.0 sq.mm) - Each 1 meter.

(1.5 sq.mm - 4.0 sq.mm) -1 No. • Copper lugs

• Neon tester (75mm, 500V) -1 No. (1.5/2.5/4.0 sq.mm) - Each 2 No’s.

• Insulation tape (19mm) -1 role.

Procedure

TASK 1 : Identify the crimpimg tool and lugs

1 Check and identify the types & size of copper lugs and PVC wire.

2 Check and identify the parts of crimping tool, and practice to operate the crimping tool.

3 Similarly, check and identify the parts of automated wire stripper and practice its usage.

TASK 2 : Crimping of lugs on PVC wire

1 Take the PVC copper multi strand wire of required length and suitable size of lug.

2 Remove the insulation of 10mm on both sides of PVC copper wire with automated wire stripper.

3 Insert the skinned part of PVC copper wire into the barrel of copper lug (Ensure that all strands of PVC copper

wire inserted properly into the barrel of lug)

4 Place the wire and lug carefully into suitable die of crimping tool.

5 Ensure that both lug & wire are properly placed in the die, and crimp the lug by pressing the handle of crimping

tool.

6 After lug is fully crimped release the handle of crimping tool which turns back automatically.

7 Remove the crimped wire from the die of crimping tool.

8 Crimp the other end of PVC copper wire in similar way.

9 Connect the crimped wire to the terminals of electrical accessories like relay, contactor, MCB etc

10 Practice the crimping with different size of wires and lugs.

19