Page 218 - Electrician - TT (Volume 1)

P. 218

ELECTRICIAN - CITS

4 Half-yearly maintenance

• Check the brushes and replace, if necessary.

• Check the windings of machines subjected to corrosive and other elements. If necessary, bake the windings

and varnish.

• Check the brush tension and adjust, if necessary.

• Check the grease in the ball and roller bearings, and make it up, where necessary, taking care to avoid

overfilling.

• Check the current input to the motor or the output of the generator and compare it with normal values.

• Drain all the oil bearings, wash with petrol to which a few drops of oil have been added; flush with lubricating

oil and refill with clean oil.

5 Annual maintenance

• Check all the high speed bearings, and renew, if necessary.

• Blow out all the machine winding thoroughly with clean dry air. Make sure that the pressure is not that high

as to damage the insulation.

• Clean and varnish the oily windings.

• Overhaul the motors which have been subjected to severe operating conditions.

• Renew the switch and fuse contacts, if damaged.

• Check the oil in the starter and the grease/oil in the bearings.

• Renew the oil in the starters subjected to damp or corrosive elements.

• Check the switch conditions, resistance to earth between motor/generator windings, control gear and

wiring.

• Check the resistance of earth connections.

• Check the air gaps in between the armature and field.

• Test the insulation of windings before and after overhauling the motors/generators.

6 Records

• Maintain a register giving one or more pages for each machine, and record therein all important inspections

and maintenance works carried out from time to time. These records should show past performance,

normal insulation level, air gap measurements, nature of repairs and interval between previous repairs and

other important information which would be of help for good performance and maintenance.

While routine maintenance could be done either during the working of the machine or during short interval `down’

periods, the planned maintenance requires to be done during holidays or by taking shut-downs of small duration.

Planned maintenance schedule needs to be decided, based on the routine maintenance reports entered in the

maintenance card.

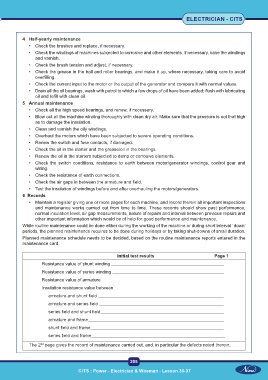

Initial test results Page 1

Resistance value of shunt winding

Resistance value of series winding

Resistance value of armature

Insulation resistance value between

armature and shunt field

armature and series field

series field and shunt field

armature and frame

shunt field and frame

series field and frame

The 2 page gives the record of maintenance carried out, and, in particular the defects noted therein.

nd

205

CITS : Power - Electrician & Wireman - Lesson 30-37