Page 178 - Electrician - TT (Volume 2)

P. 178

ELECTRICIAN - CITS ELECTRICIAN - CITS

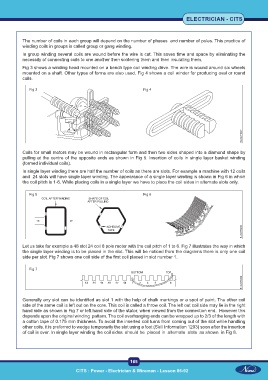

The number of coils in each group will depend on the number of phases and number of poles. This practice of

winding coils in groups is called group or gang winding.

In group winding several coils are wound before the wire is cut. This saves time and space by eliminating the

necessity of connecting coils to one another then soldering them and then insulating them.

Fig 3 shows a winding head mounted on a bench type coil winding drive. The wire is wound around six wheels

mounted on a shaft. Other types of forms are also used. Fig 4 shows a coil winder for producing oval or round

coils.

Fig 3 Fig 4

Coils for small motors may be wound in rectangular form and then two sides shaped into a diamond shape by

pulling at the centre of the opposite ends as shown in Fig 5. Insertion of coils in single layer basket winding

(formed individual coils).

In single layer winding there are half the number of coils as there are slots. For example a machine with 12 coils

and 24 slots will have single layer winding. The appearance of a single layer winding is shown in Fig 6 in which

the coil pitch is 1-6. While placing coils in a single layer we have to place the coil sides in alternate slots only.

Fig 5 Fig 6

Let us take for example a 48 slot 24 coil 8 pole motor with the coil pitch of 1 to 6. Fig 7 illustrates the way in which

the single layer winding is to be placed in the slot. This will be noticed from the diagrams there is only one coil

side per slot. Fig 7 shows one coil side of the first coil placed in slot number 1.

Fig 7

Generally any slot can be identified as slot 1 with the help of chalk markings or a spot of paint. The other coil

side of the same coil is left out on the core. This coil is called a throw coil. The left out coil side may lie in the right

hand side as shown in Fig 7 or left hand side of the stator, when viewed from the connection end. However this

depends upon the original winding pattern. The coil overhanging ends can be wrapped up to 2/3 of the length with

a cotton tape of 0.175 mm thickness. To avoid the inserted coil turns from coming out of the slot while handling

other coils, it is preferred to wedge temporarily the slot using a foot (Skill Information 1203) soon after the insertion

of coil is over. In single layer winding the coil sides should be placed in alternate slots as shown in Fig 8.

164 165

CITS : Power - Electrician & Wireman - Lesson 86-92 CITS : Power - Electrician & Wireman - Lesson 86-92