Page 181 - Electrician - TT (Volume 2)

P. 181

ELECTRICIAN - CITS ELECTRICIAN - CITS

Further the connection end of the winding in the stator is to be identified from the data with respect to the terminal

box.

Referring to the developed diagram (Fig 12) and Table 1, if the bottom coil side 1 is inserted in slot 1, then the

other coil side of the same coil which is 12, should be inserted in the slot number 6 as a top coil side. As such

there should be a certain approved procedure to start the winding.

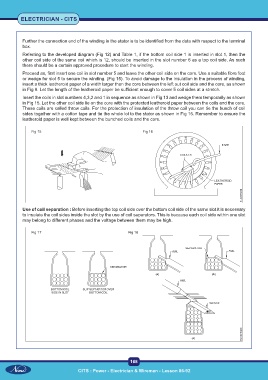

Proceed as, first insert one coil in slot number 5 and leave the other coil side on the core. Use a suitable fibre foot

or wedge for slot 5 to secure the winding. (Fig 15). To avoid damage to the insulation in the process of winding,

insert a thick leatheroid paper of a width larger than the core between the left out coil side and the core, as shown

in Fig 8. Let the length of the leatheroid paper be sufficient enough to cover 5 coil sides at a stretch.

Insert the coils in slot numbers 4,3,2 and 1 in sequence as shown in Fig 13 and wedge them temporarily as shown

in Fig 15. Let the other coil side lie on the core with the protected leatheroid paper between the coils and the core.

These coils are called throw coils. For the protection of insulation of the throw coil you can tie the bunch of coil

sides together with a cotton tape and tie the whole lot to the stator as shown in Fig 16. Remember to ensure the

leatheroid paper is well kept between the bunched coils and the core.

Fig 15 Fig 16

Use of coil separation : Before inserting the top coil side over the bottom coil side of the same slot it is necessary

to insulate the coil sides inside the slot by the use of coil seperators. This is because each coil side within one slot

may belong to different phases and the voltage between them may be high.

Fig 17 Fig 18

168 169

CITS : Power - Electrician & Wireman - Lesson 86-92 CITS : Power - Electrician & Wireman - Lesson 86-92