Page 138 - CITS - Electronic Mechanic - TT - 2024

P. 138

ELECTRONICS MECHANIC - CITS

Through-Hole Plating: Conductive holes connect traces on both sides, allowing for more complex circuits.

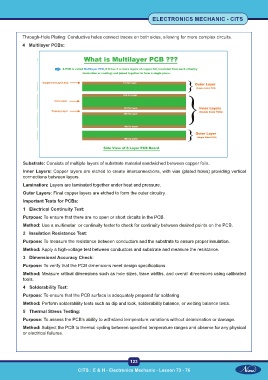

4 Multilayer PCBs:

Substrate: Consists of multiple layers of substrate material sandwiched between copper foils.

Inner Layers: Copper layers are etched to create interconnections, with vias (plated holes) providing vertical

connections between layers.

Lamination: Layers are laminated together under heat and pressure.

Outer Layers: Final copper layers are etched to form the outer circuitry.

Important Tests for PCBs:

1 Electrical Continuity Test:

Purpose: To ensure that there are no open or short circuits in the PCB.

Method: Use a multimetar or continuity tester to check for continuity between desired points on the PCB.

2 Insulation Resistance Test:

Purpose: To measure the resistance between conductors and the substrate to ensure proper insulation.

Method: Apply a high-voltage test between conductors and substrate and measure the resistance.

3 Dimensional Accuracy Check:

Purpose: To verify that the PCB dimensions meet design specifications.

Method: Measure critical dimensions such as hole sizes, trace widths, and overall dimensions using calibrated

tools.

4 Solderability Test:

Purpose: To ensure that the PCB surface is adequately prepared for soldering.

Method: Perform solderability tests such as dip and look, solderability balance, or wetting balance tests.

5 Thermal Stress Testing:

Purpose: To assess the PCB’s ability to withstand temperature variations without delamination or damage.

Method: Subject the PCB to thermal cycling between specified temperature ranges and observe for any physical

or electrical failures.

123

CITS : E & H - Electronics Mechanic - Lesson 73 - 76