Page 18 - CITS - Electronic Mechanic - TT - 2024

P. 18

ELECTRONICS MECHANIC - CITS

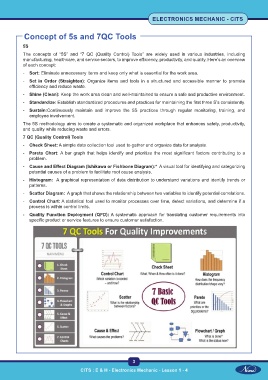

Concept of 5s and 7QC Tools

5S

The concepts of “5S” and “7 QC (Quality Control) Tools” are widely used in various industries, including

manufacturing, healthcare, and service sectors, to improve efficiency, productivity, and quality. Here’s an overview

of each concept:

- Sort: Eliminate unnecessary items and keep only what is essential for the work area.

- Set in Order (Straighten): Organize items and tools in a structured and accessible manner to promote

efficiency and reduce waste.

- Shine (Clean): Keep the work area clean and well-maintained to ensure a safe and productive environment.

- Standardize: Establish standardized procedures and practices for maintaining the first three S’s consistently.

- Sustain:Continuously maintain and improve the 5S practices through regular monitoring, training, and

employee involvement.

The 5S methodology aims to create a systematic and organized workplace that enhances safety, productivity,

and quality while reducing waste and errors.

7 QC (Quality Control) Tools

- Check Sheet: A simple data collection tool used to gather and organize data for analysis.

- Pareto Chart: A bar graph that helps identify and prioritize the most significant factors contributing to a

problem.

- Cause and Effect Diagram (Ishikawa or Fishbone Diagram):* A visual tool for identifying and categorizing

potential causes of a problem to facilitate root cause analysis.

- Histogram: A graphical representation of data distribution to understand variations and identify trends or

patterns.

- Scatter Diagram: A graph that shows the relationship between two variables to identify potential correlations.

- Control Chart: A statistical tool used to monitor processes over time, detect variations, and determine if a

process is within control limits.

- Quality Function Deployment (QFD): A systematic approach for translating customer requirements into

specific product or service features to ensure customer satisfaction.

3

CITS : E & H - Electronics Mechanic - Lesson 1 - 4