Page 288 - CITS - Electronic Mechanic - TT - 2024

P. 288

ELECTRONICS MECHANIC - CITS

2 It has pilot lamp to indicate. It will glow if the temperature is under predetermined value, otherwise not glow.

3 Cost is high.

4 As the temperature is controlled automatically through thermostatic switch, the risk of burning the cloth is mini-

mized.

Non-Automatic:

1 It does not contain thermostat switch. Thus temperature is not regulated.

2 User has to switch ON or OFF the supply to iron according to the heat requirement.

3 There is no pilot lamp to point out the temperature condition whether it is within the limit or not.

4 Cost is low.

5 Overheat might burn the cloth. Thus more care is needed.

Automatic electric irons are more common as compared to non-automatic due to their safety benefits.

Components of an electric iron:

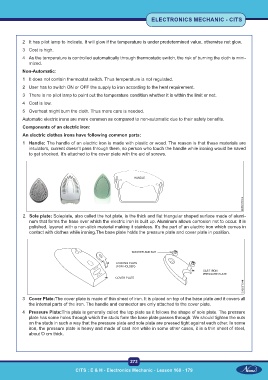

An electric clothes irons have following common parts:

1 Handle: The handle of an electric iron is made with plastic or wood. The reason is that these materials are

insulators, current doesn’t pass through them, so person who touch the handle while ironing would be saved

to get shocked. It’s attached to the cover plate with the aid of screws.

2 Sole plate: Soleplate, also called the hot plate, is the thick and flat triangular shaped surface made of alumi-

num that forms the base over which the electric iron is built up. Aluminum allows corrosion not to occur. It is

polished, layered with a non-stick material making it stainless. It’s the part of an electric iron which comes in

contact with clothes while ironing.The base plate holds the pressure plate and cover plate in position.

3 Cover Plate:The cover plate is made of thin sheet of iron. It is placed on top of the base plate and it covers all

the internal parts of the iron. The handle and connector are only attached to the cover plate.

4 Pressure Plate:This plate is generally called the top plate as it follows the shape of sole plate. The pressure

plate has some holes through which the studs form the base plate passes through. We should tighten the nuts

on the studs in such a way that the pressure plate and sole plate are pressed tight against each other. In some

iron, the pressure plate is heavy and made of cast iron while in some other cases, it is a thin sheet of steel,

about Ό cm thick.

273

CITS : E & H - Electronics Mechanic - Lesson 160 - 179