Page 88 - CITS - Electronic Mechanic - TT - 2024

P. 88

ELECTRONICS MECHANIC - CITS

J – Type Thermocouple

Positive wire — Iron Negative wire — Constantan It can be used up to 1000oC. It is a very common type of

thermocouple. Its stability is high.

K — Type Thermocouple

Positive wire — Chromel Negative wire — Alumel It can be used up to 1200oC. It is a widely used type of

thermocouple. It is a cheaper type as compared to other types.

S – Type Thermocouple

Positive wire — Platinum 10% Rohodium Negative wire — Platinum It can be used up to 1400oC. It has very high

precision thus used for very high accuracy requirements.

The current will flow from + ve marked lead to the – ve marked lead. In thermocouples, negative lead is generally

a red colored wire. The color of positive lead will be according to its type.

Advantages:

They follow the temperature changes with a small time-lag.So it can be used in the applications where very rapid

changes in temperature take places.It responds to those changes very quickly.These are very convenient for

measuring the temperature at one particular point in any apparatus or setup.

Disadvantages:

They have very low accuracy. So they cannot be used for very high precision measurement.They have to protect

against contamination to ensure long life.They are placed at a very large distance from the measuring device.

This increases errors in the result.

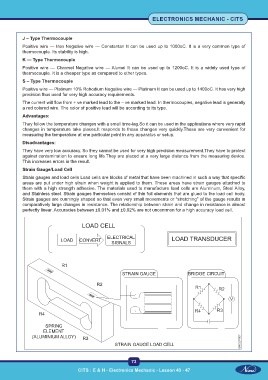

Strain Gauge/Load Cell

Strain gauges and load cells Load cells are blocks of metal that have been machined in such a way that specific

areas are put under high strain when weight is applied to them. These areas have strain gauges attached to

them with a high strength adhesive. The materials used to manufacture load cells are Aluminum, Steel Alloy,

and Stainless steel. Strain gauges themselves consist of thin foil elements that are glued to the load cell body.

Strain gauges are cunningly shaped so that even very small movements or “stretching” of the gauge results in

comparatively large changes in resistance. The relationship between strain and change in resistance is almost

perfectly linear. Accuracies between ±0.01% and ±0.02% are not uncommon for a high accuracy load cell.

73

CITS : E & H - Electronics Mechanic - Lesson 43 - 47