Page 102 - CITS - Fitter Trade Pactical - Volume - 2

P. 102

FITTER - CITS

• Fix the M 12 first tap in tap wrench.

• Screw a matching nut on the first tap to the required distance for 14 mm to act as a depth stop.

• Cut internal thread in blind hole to the required depth 14 mm.

• Remove the metal chips, if any from the threaded blind hole.

• Similarly, fix M 12 second tap and third tap in tap wrench one by one and cut the thread to form full thread.

• Clean the threaded hole without burrs.

• Repeat the above process to cut internal thread in other drilled blind hole.

• Check the threaded hole using the M10, and M12 matching bolts by screwing.

• Apply thin coat of oil and pressure it for evaluation

Use cutting fluid while cutting the thread.

Internal threading of through holes using hand taps

Objectives: At the end of this exercise you shall be able to

• practice internal threading of through holes using hand taps

Determining the tap drill size

For cutting internal threads, it is necessary to determine the size of the hole (tap drill size). This can be calculated

using the formula or can be chosen from the table of the tap drill sizes.

Procedure

Drill the hole to the required tap drill size.

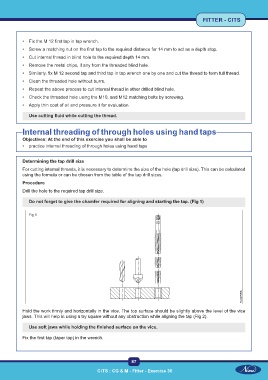

Do not forget to give the chamfer required for aligning and starting the tap. (Fig 1)

Fig 1

Hold the work firmly and horizontally in the vice. The top surface should be slightly above the level of the vice

jaws. This will help in using a try square without any obstruction while aligning the tap (Fig 2).

Use soft jaws while holding the finished surface on the vice.

Fix the first tap (taper tap) in the wrench.

87

CITS : CG & M - Fitter - Exercise 30