Page 104 - CITS - Fitter Trade Pactical - Volume - 2

P. 104

FITTER - CITS

Check the tap alignment again with a try square.

Fit the tap wrench, and tighten without disturbing the tap alignment.

Make one or two turns and check the alignment.

The tap alignment should be corrected within the first few turns. Afterwards this cannot be done for the threads

will break.

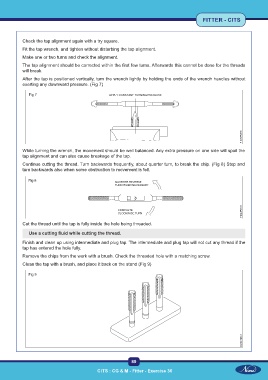

After the tap is positioned vertically, turn the wrench lightly by holding the ends of the wrench handles without

exerting any downward pressure. (Fig 7)

Fig 7

While turning the wrench, the movement should be well balanced. Any extra pressure on one side will spoil the

tap alignment and can also cause breakage of the tap.

Continue cutting the thread. Turn backwards frequently, about quarter turn, to break the chip. (Fig 8) Stop and

turn backwards also when some obstruction to movement is felt.

Fig 8

Cut the thread until the tap is fully inside the hole being threaded.

Use a cutting fluid while cutting the thread.

Finish and clean up using intermediate and plug tap. The intermediate and plug tap will not cut any thread if the

tap has entered the hole fully.

Remove the chips from the work with a brush. Check the threaded hole with a matching screw.

Clean the tap with a brush, and place it back on the stand (Fig 9)

Fig 9

89

CITS : CG & M - Fitter - Exercise 30 CITS : CG & M - Fitter - Exercise 30