Page 122 - CITS - Fitter Trade Pactical - Volume - 2

P. 122

FITTER - CITS

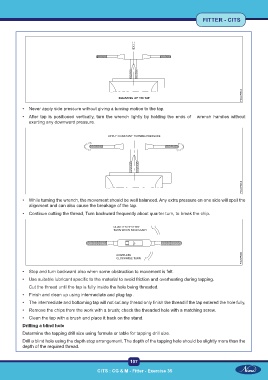

• Never apply side pressure without giving a turning motion to the tap.

• After tap is positioned vertically, turn the wrench lightly by holding the ends of wrench handles without

exerting any downward pressure.

• While turning the wrench, the movement should be well balanced. Any extra pressure on one side will spoil the

alignment and can also cause the breakage of the tap.

• Continue cutting the thread, Turn backward frequently about quarter turn, to break the chip.

• Stop and turn backward also when some obstruction to movement is felt.

• Use suitable lubricant specific to the material to avoid friction and overheating during tapping.

Cut the thread until the tap is fully inside the hole being threaded.

• Finish and clean up using intermediate and plug tap .

• The intermediate and bottoming tap will not cut any thread only finish the thread if the tap entered the hole fully,

• Remove the chips from the work with a brush; check the threaded hole with a matching screw.

• Clean the tap with a brush and place it back on the stand.

Drilling a blind hole

Determine the tapping drill size using formula or table for tapping drill size.

Drill a blind hole using the depth stop arrangement. The depth of the tapping hole should be slightly more than the

depth of the required thread.

107

CITS : CG & M - Fitter - Exercise 35 CITS : CG & M - Fitter - Exercise 35