Page 118 - CITS - Fitter Trade Pactical - Volume - 2

P. 118

FITTER - CITS

Job Sequence

• Check the raw material for its size.

• File blank size to Ø 13.9 mm x 40 mm length as per drawing.

• File chamfer in both ends to 2 mm x 45°

• Hold the job at 90° in bench vice.

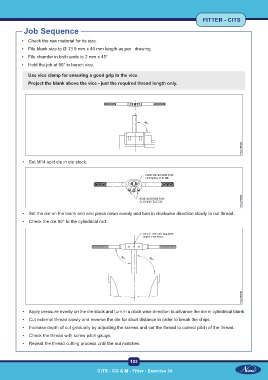

Use vice clamp for ensuring a good grip in the vice.

Project the blank above the vice - just the required thread length only.

• Set M14 split die in die stock.

• Set the die on the blank end and press down evenly and turn in clockwise direction slowly to cut thread.

• Check the die 90° to the cylindrical rod.

• Apply pressure evenly on the die stock and turn in a clock wise direction to advance the die in cylindrical blank.

• Cut external thread slowly and reverse the die for short distance in order to break the chips.

• Increase depth of cut gradually by adjusting the screws and cut the thread to correct pitch of the thread.

• Check the thread with screw pitch gauge.

• Repeat the thread cutting process until the nut matches.

103

CITS : CG & M - Fitter - Exercise 34