Page 113 - CITS - Fitter Trade Pactical - Volume - 2

P. 113

FITTER - CITS

EXERCISE 33: Demonstration on removal of broken Taps

or Studs from through hole and blind hole

Objectives

At the end of this exercise you shall be able to

• different methods of removing broken taps.

• causes for breakage of stud.

• different methods for removing broken stud.

Job Sequence

Following methods can apply to removal of broken taps or studs from through or blind hole.

Taps broken below the surface pose a problem for removing. Any one of the several methods can be used.

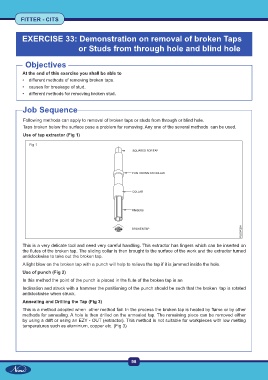

Use of tap extractor (Fig 1)

Fig 1

This is a very delicate tool and need very careful handling. This extractor has fingers which can be inserted on

the flutes of the broken tap. The sliding collar is then brought to the surface of the work and the extractor turned

anticlockwise to take out the broken tap.

A light blow on the broken tap with a punch will help to relieve the tap if it is jammed inside the hole.

Use of punch (Fig 2)

In this method the point of the punch is placed in the flute of the broken tap in an

Inclination and struck with a hammer the positioning of the punch should be such that the broken tap is rotated

anticlockwise when struck.

Annealing and Drilling the Tap (Fig 3)

This is a method adopted when other method fail. In the process the broken tap is heated by flame or by other

methods for annealing. A hole is then drilled on the annealed tap. The remaining piece can be removed either

by using a drift or using an EZY - OUT (extractor). This method is not suitable for workpieces with low melting

temperatures such as aluminium, copper etc. (Fig 3)

98