Page 114 - CITS - Fitter Trade Pactical - Volume - 2

P. 114

FITTER - CITS

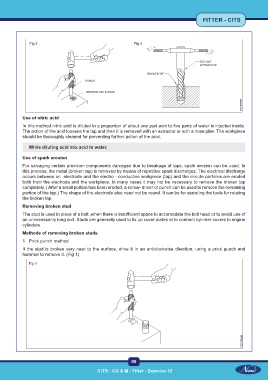

Fig 2 Fig 3

Use of nitric acid

In this method nitric acid is diluted in a proportion of about one part acid to five parts of water is injected inside.

The action of the acid loosens the tap and then it is removed with an extractor or with a nose plier. The workpiece

should be thoroughly cleaned for preventing further action of the acid.

While diluting acid mix acid to water.

Use of spark erosion

For salvaging certain precision components damaged due to breakage of taps, spark erosion can be used. In

this process, the metal (broken tap) is removed by means of repetitive spark discharges. The electrical discharge

occurs between an electrode and the electro - conductive workpiece (tap) and the minute particles are eroded

both from the electrode and the workpiece. In many cases it may not be necessary to remove the broken tap

completely. ( After a small portion has been eroded, a screw- driver or punch can be used to remove the remaining

portion of the tap.) The shape of the electrode also need not be round. It can be for assisting the tools for rotating

the broken tap.

Removing broken stud

The stud is used in place of a bolt ,when there is insufficient space to accomodate the bolt head or to avoid use of

an unnecessarily long bolt. Studs are generally used to fix up cover plates or to connect cylinder covers to engine

cylinders.

Methods of removing broken studs

1 Prick punch method

If the stud is broken very near to the surface, drive it in an anticlockwise direction, using a prick punch and

hammer to remove it. (Fig 1)

Fig 1

99

CITS : CG & M - Fitter - Exercise 33