Page 193 - CITS - Fitter Trade Pactical - Volume - 2

P. 193

FITTER - CITS

Fig 5

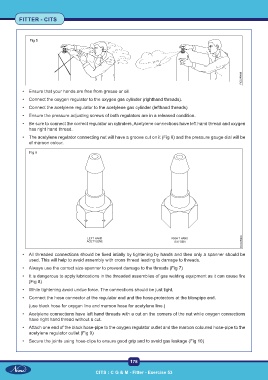

• Ensure that your hands are free from grease or oil.

• Connect the oxygen regulator to the oxygen gas cylinder (righthand threads).

• Connect the acetylene regulator to the acetylene gas cylinder (lefthand threads)

• Ensure the pressure adjusting screws of both regulators are in a released condition.

• Be sure to connect the correct regulator on cylinders, Acetylene connections have left hand thread and oxygen

has right hand thread.

• The acetylene regulator connecting nut will have a groove cut on it (Fig 6) and the pressure gauge dial will be

of maroon colour.

Fig 6

• All threaded connections should be fixed intially by tightening by hands and then only a spanner should be

used. This will help to avoid assembly with cross thread leading to damage to threads.

• Always use the correct size spanner to prevent damage to the threads (Fig 7)

• It is dangerous to apply lubrications in the threaded assemblies of gas welding equipment as it can cause fire

(Fig 8)

• While tightening avoid undue force. The connections should be just tight.

• Connect the hose connector at the regulator end and the hose-protectors at the blowpipe end.

(use black hose for oxygen line and maroon hose for acetylene line.)

• Acetylene connections have left hand threads with a cut on the corners of the nut while oxygen connections

have right hand thread without a cut.

• Attach one end of the black hose-pipe to the oxygen regulator outlet and the maroon coloured hose-pipe to the

acetylene regulator outlet (Fig 9)

• Secure the joints using hose-clips to ensure good grip and to avoid gas leakage (Fig 10)

178

CITS : C G & M - Fitter - Exercise 53