Page 201 - CITS - Fitter Trade Pactical - Volume - 2

P. 201

FITTER - CITS

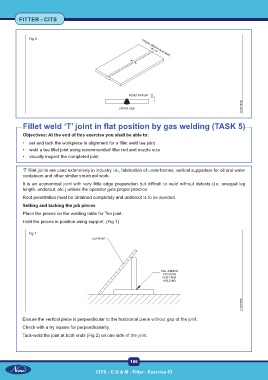

Fig 5

Fillet weld ‘T’ joint in flat position by gas welding (TASK 5)

Objectives: At the end of this exercise you shall be able to:

• set and tack the workpiece in alignment for a fillet weld tee joint

• weld a tee fillet joint using recommended filler rod and nozzle size

• visually inspect the completed joint.

‘T’ fillet joints are used extensively in industry i.e., fabrication of underframes, vertical supporters for oil and water

containers and other similar structural work.

It is an economical joint with very little edge preparation but difficult to weld without defects (i.e. unequal leg

length, undercut, etc.) unless the operator gets proper practice.

Root penetration must be obtained completely and undercut is to be avoided.

Setting and tacking the job pieces

Place the pieces on the welding table for Tee joint.

Hold the pieces in position using support. (Fig 1)

Fig 1

Ensure the vertical piece is perpendicular to the horizontal piece without gap of the joint.

Check with a try square for perpendicularity.

Tack-weld the joint at both ends (Fig 2) on one side of the joint.

186

CITS : C G & M - Fitter - Exercise 53