Page 67 - CITS - Fitter Trade Pactical - Volume - 2

P. 67

FITTER - CITS

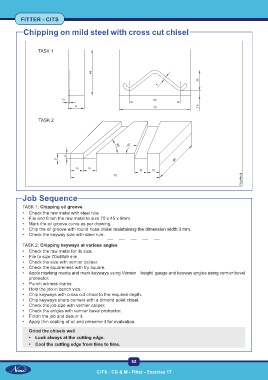

Chipping on mild steel with cross cut chisel

TASK 1

TASK 2

Job Sequence

Job Sequence

TASK 1: Chipping oil groove

• Check the raw metal with steel rule

• File and finish the raw metal to size 70 x 45 x 9mm

• Mark the oil groove curve as per drawing.

• Chip the oil groove with round nose chisel maintaining the dimension width 3 mm.

• Check the keyway size with steel rule.

TASK 2: Chipping keyways at various angles

• Check the raw metal for its size.

• File to size 70x48x9 mm.

• Check the size with vernier caliper.

• Check the squareness with try square.

• Apply marking media and mark keyways using Vernier height gauge and keyway angles using vernier bevel

protractor.

• Punch witness marks.

• Hold the job in bench vice.

• Chip keyways with cross cut chisel to the required depth.

• Chip keyways sharp corners with a dimond point chisel.

• Check the job size with vernier caliper.

• Check the anlges with vernier bevel protractor.

• Finish the job and deburr it.

• Apply thin coating of oil and preserve it for evalvation.

Grind the chisels well

• Look always at the cutting edge.

• Cool the cutting edge from time to time.

52

CITS : CG & M - Fitter - Exercise 17