Page 75 - CITS - Fitter Trade Pactical - Volume - 2

P. 75

FITTER - CITS

EXERCISE 21: Scraping of flat bearing surface and their

fitting

Objectives

At the end of this exercise you shall be able to

• find high spots on curved surfaces using prussion blue

• scrap curved surfaces and test.

Skill Sequence

Job Sequence

A half round scraper is the most suitable scraper for scraping curved surfaces. This method of scraping differs

from that of flat scraping.

Method

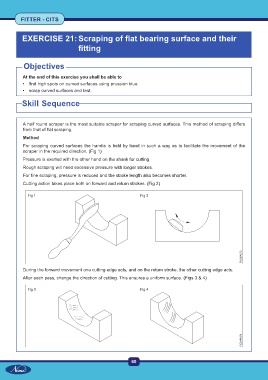

For scraping curved surfaces the handle is held by hand in such a way as to facilitate the movement of the

scraper in the required direction. (Fig 1)

Pressure is exerted with the other hand on the shank for cutting.

Rough scraping will need excessive pressure with longer strokes.

For fine scraping, pressure is reduced and the stroke length also becomes shorter.

Cutting action takes place both on forward and return strokes. (Fig 2)

Fig 1 Fig 2

During the forward movement one cutting edge acts, and on the return stroke, the other cutting edge acts.

After each pass, change the direction of cutting. This ensures a uniform surface. (Figs 3 & 4)

Fig 3 Fig 4

60