Page 96 - CITS - Fitter Trade Pactical - Volume - 2

P. 96

FITTER - CITS

Job Sequence

• Hold the blunt twist drill properly in both hands.

• Place the drill on tool rest.

• Touch the cutting edge of a twist drill in grinding wheel face maintaining 31°angle from grinding stone.

• Twist the drill slightly on wheel face and grind one cutting edge the required angle to get 59°.

• Similarly, grind the other cutting edge to the required angle to get 59° maintaining the cutting edges length

equal.

Swing the shank of the drill slightly down wards while grinding.

While sharpening drill, the cutting edges length and angles should be equal.

• Check the cutting angle and cutting edge length in to drill grinding gauge.

• Switch off the grinding machine and clean properly.

Wear safety goggles while sharpening twist drills.

Skill Sequence

Job Sequence

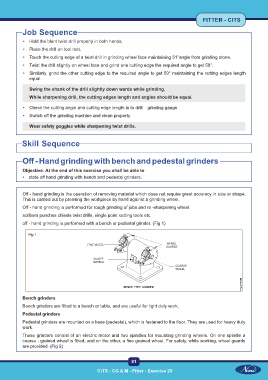

Off - Hand grinding with bench and pedestal grinders

Objective: At the end of this exercise you shall be able to

• state off hand grinding with bench and pedestal grinders.

Off - hand grinding is the operation of removing material which does not require great accuracy in size or shape.

This is carried out by pressing the workpiece by hand against a grinding wheel.

Off - hand grinding is performed for rough grinding of jobs and re -sharpening wheel.

scribers punches chisels twist drills, single point cutting tools etc.

off - hand grinding is performed with a bench or pedestal grinder. (Fig 1)

Fig 1

Bench grinders

Bench grinders are fitted to a bench or table, and are useful for light duty work.

Pedestal grinders

Pedestal grinders are mounted on a base (pedestal), which is fastened to the floor. They are used for heavy duty

work.

These grinders consist of an electric motor and two spindles for mounting grinding wheels. On one spindle a

coarse - grained wheel is fitted, and on the other, a fine grained wheel. For safety, while working, wheel guards

are provided. (Fig 2)

81

CITS : CG & M - Fitter - Exercise 29