Page 93 - CITS - Fitter Trade Pactical - Volume - 2

P. 93

FITTER - CITS

• Fix Ø 6mm drill in drilling machine spindle through drill chuck and drill pilot holes for both through and blind

holes.

• Use soluble oil as coolants for drilling Mild steel workpiece .

• Fix Ø 8.5 mm drill and drill through hole as per drawing.

• Fix Ø 10.5 mm drill and drill blind hole to the required depth of 14 mm using depth stop of drilling machine.

• Use kerosene oil for drilling in Aluminum flat.

• File and de - burr in all the surfaces of the job.

• Apply a thin coat of oil and preserve it for evaluation.

Skill Sequence

Job Sequence

Drilling blind holes

Objective : At the end of this exercise you shall be able to

• drill blind holes to the required depth using the depth stops.

Method of controlling depth of blind holes

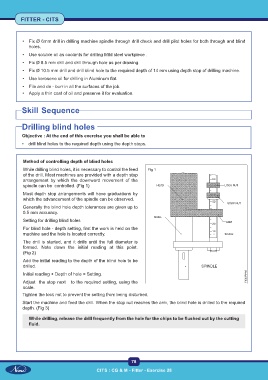

While drilling blind holes, it is necessary to control the feed Fig 1

of the drill. Most machines are provided with a depth stop

arrangement by which the downward movement of the

spindle can be controlled. (Fig 1)

Most depth stop arrangements will have graduations by

which the advancement of the spindle can be observed.

Generally the blind hole depth tolerances are given up to

0.5 mm accuracy.

Setting for drilling blind holes

For blind hole - depth setting, first the work is held on the

machine and the hole is located correctly.

The drill is started, and it drills until the full diameter is

formed. Note down the initial reading at this point.

(Fig 2)

Add the initial reading to the depth of the blind hole to be

drilled.

Initial reading + Depth of hole = Setting.

Adjust the stop next to the required setting, using the

scale.

Tighten the lock nut to prevent the setting from being disturbed.

Start the machine and feed the drill. When the stop nut reaches the arm, the blind hole is drilled to the required

depth. (Fig 3)

While drilling, release the drill frequently from the hole for the chips to be flushed out by the cutting

fluid.

78

CITS : CG & M - Fitter - Exercise 28