Page 88 - CITS - Fitter Trade Pactical - Volume - 2

P. 88

FITTER - CITS

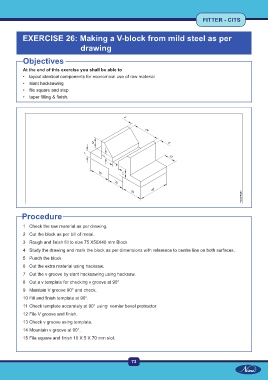

EXERCISE 26: Making a V-block from mild steel as per

drawing

Objectives

At the end of this exercise you shall be able to

• layout identical components for economical use of raw material

• slant hacksawing

• file square and step

• taper filling & finish.

Procedure

1 Check the raw material as per drawing.

2 Cut the block as per bill of metal.

3 Rough and finish fill to size 75 X50X40 mm Block

4 Study the drawing and mark the block as per dimensions with reference to centre line on both surfaces.

5 Punch the block

6 Cut the extra material using hacksaw.

7 Cut the v groove by slant hacksawing using hacksaw.

8 Cut a v template for checking v groove at 90°

9 Maintain V groove 90° and check.

10 Fill and finish template at 90°.

11 Check template accurately at 90° using vernier bevel protractor.

12 File V groove and finish.

13 Check v groove using template.

14 Mountain v groove at 90°.

15 File square and finish 10 X 5 X 70 mm slot.

73