Page 163 - CITS - Fitter Trade Practical - Volume -2

P. 163

FITTER - CITS

Job Sequence

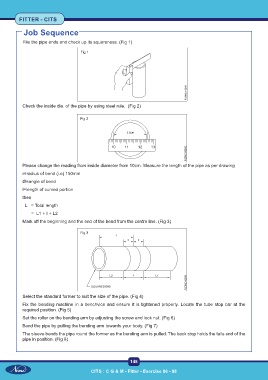

File the pipe ends and check up its squareness. (Fig 1)

Check the inside dia. of the pipe by using steel rule. (Fig 2)

Please change the reading from inside diameter from 10cm. Measure the length of the pipe as per drawing

r=radius of bend (i.e) 150mm

Ø=angle of bend

l=length of curved portion

then

L = Total length

= L1 + l + L2

Mark off the beginning and the end of the bend from the centre line. (Fig 3)

Select the standard former to suit the size of the pipe. (Fig 4)

Fix the bending machine in a benchvice and ensure it is tightened properly. Locate the tube stop bar at the

required position. (Fig 5)

Set the roller on the bending arm by adjusting the screw and lock nut. (Fig 6)

Bend the pipe by pulling the bending arm towards your body. (Fig 7)

The sleeve bends the pipe round the former as the bending arm is pulled. The back stop holds the tails end of the

pipe in position. (Fig 8)

148

CITS : C G & M - Fitter - Exercise 86 - 88