Page 211 - CITS - Fitter Trade Practical - Volume -2

P. 211

FITTER - CITS

Note : Use internal snap ring pliers to remove snap ring

Keep all the components of pump in proper manner and in clean place.

TASK 2: Replace the worn out components and reassemble the gear pump

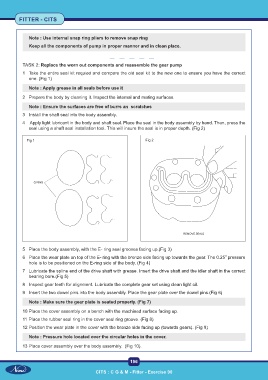

1 Take the entire seal kit requied and compare the old seal kit to the new one to ensure you have the correct

one. (Fig 1)

Note : Apply grease in all seals before use it

2 Prepare the body by cleaning it. Inspect the internal and mating surfaces.

Note : Ensure the surfaces are free of burrs an scratches

3 Install the shaft seal into the body assembly.

4 Apply light lubricant in the body and shaft seal. Place the seal in the body assembly by hand. Then, press the

seal using a shaft seal installation tool. This will insure the seal is in proper depth. (Fig 2)

Fig 1 Fig 2

5 Place the body assembly, with the E- ring seal grooves facing up.(Fig 3)

6 Place the wear plate on top of the E- ring with the bronze side facing up towards the gear. The 0.25” pressure

hole is to be positioned on the E-ring side of the body. (Fig 4)

7 Lubricate the spline end of the drive shaft with grease. Insert the drive shaft and the idler shaft in the correct

bearing bore.(Fig 5)

8 Inspect gear teeth for alignment. Lubricate the complete gear set using clean light oil.

9 Insert the two dowel pins into the body assembly. Place the gear plate over the dowel pins.(Fig 6)

Note : Make sure the gear plate is seated properly. (Fig 7)

10 Place the cover assembly on a bench with the machined surface facing up.

11 Place the rubber seal ring in the cover seal ring groove. (Fig 8)

12 Position the wear plate in the cover with the bronze side facing up (towards gears). (Fig 9)

Note : Pressure hole located over the circular holes in the cover.

13 Place cover assembly over the body assembly. (Fig 10).

196

CITS : C G & M - Fitter - Exercise 90