Page 236 - CITS - Fitter Trade Practical - Volume -2

P. 236

FITTER - CITS

For all bearings having interference fit in the housing

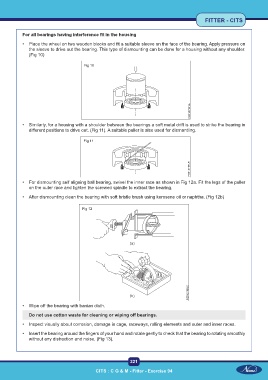

• Place the wheel on two wooden blocks and fit a suitable sleeve on the face of the bearing. Apply pressure on

the sleeve to drive out the bearing. This type of dismounting can be done for a housing without any shoulder.

(Fig 10)

• Similarly, for a housing with a shoulder between the bearings a soft metal drift is used to strike the bearing in

different positions to drive out. (Fig 11). A suitable puller is also used for dismantling.

• For dismounting self aligning ball bearing, swivel the inner race as shown in Fig 12a. Fit the legs of the puller

on the outer race and tighten the screwed spindle to extract the bearing.

• After dismounting clean the bearing with soft bristle brush using kerosene oil or naphtha. (Fig 12b)

• Wipe off the bearing with banian cloth.

Do not use cotton waste for cleaning or wiping off bearings.

• Inspect visually about corrosion, damage in cage, raceways, rolling elements and outer and inner races.

• Insert the bearing around the fingers of your hand and rotate gently to check that the bearing to rotating smoothly

without any distraction and noise. (Fig 13).

221

CITS : C G & M - Fitter - Exercise 94