Page 66 - CITS - Fitter Trade Practical - Volume -2

P. 66

FITTER - CITS

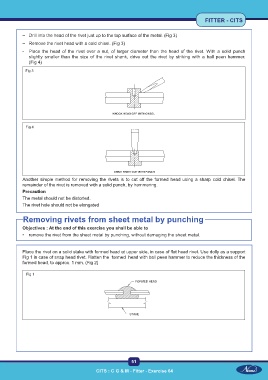

– Drill into the head of the rivet just up to the top surface of the metal. (Fig 3)

– Remove the rivet head with a cold chisel. (Fig 3)

- Place the head of the rivet over a nut, of larger diameter than the head of the rivet. With a solid punch

slightly smaller than the size of the rivet shank, drive out the rivet by striking with a ball peen hammer.

(Fig 4)

Fig 3

Fig 4

Another simple method for removing the rivets is to cut off the formed head using a sharp cold chisel. The

remainder of the rivet is removed with a solid punch, by hammering.

Precaution

The metal should not be distorted.

The rivet hole should not be elongated

Removing rivets from sheet metal by punching

Objectives : At the end of this exercise you shall be able to

• remove the rivet from the sheet metal by punching, without damaging the sheet metal.

Place the rivet on a solid stake with formed head at upper side, in case of flat head rivet. Use dolly as a support

Fig 1 in case of snap head rivet. Flatten the formed head with ball peen hammer to reduce the thickness of the

formed head, to approx. 1 mm. (Fig 2)

Fig 1

51

CITS : C G & M - Fitter - Exercise 64